Producing Specialty Coffee for the First Time

| Origin

Written by Livia Mundim

Table of Contents

Fazenda Santa Fé da Vereda, Cerrado Mineiro

For the first time this year, I undertook the production of specialty coffee micro-lots on my family’s coffee farm, Fazenda Santa Fé da Vereda, Cerrado Mineiro, in Minas Gerais. I invited two friends and professionals in post-harvest processing to assist. Marquinho do Cerrado and Matheus Tinoco helped me with the harvest, milling, and the preparation required to export these specialty coffee lots.

I used Cropster origin to track and monitor all the production processes. I monitored the yield from each step, realized the benefit in organized data collection, studied the final reports to understand the impact of my decisions, and linked the final quality results to each step of the process.

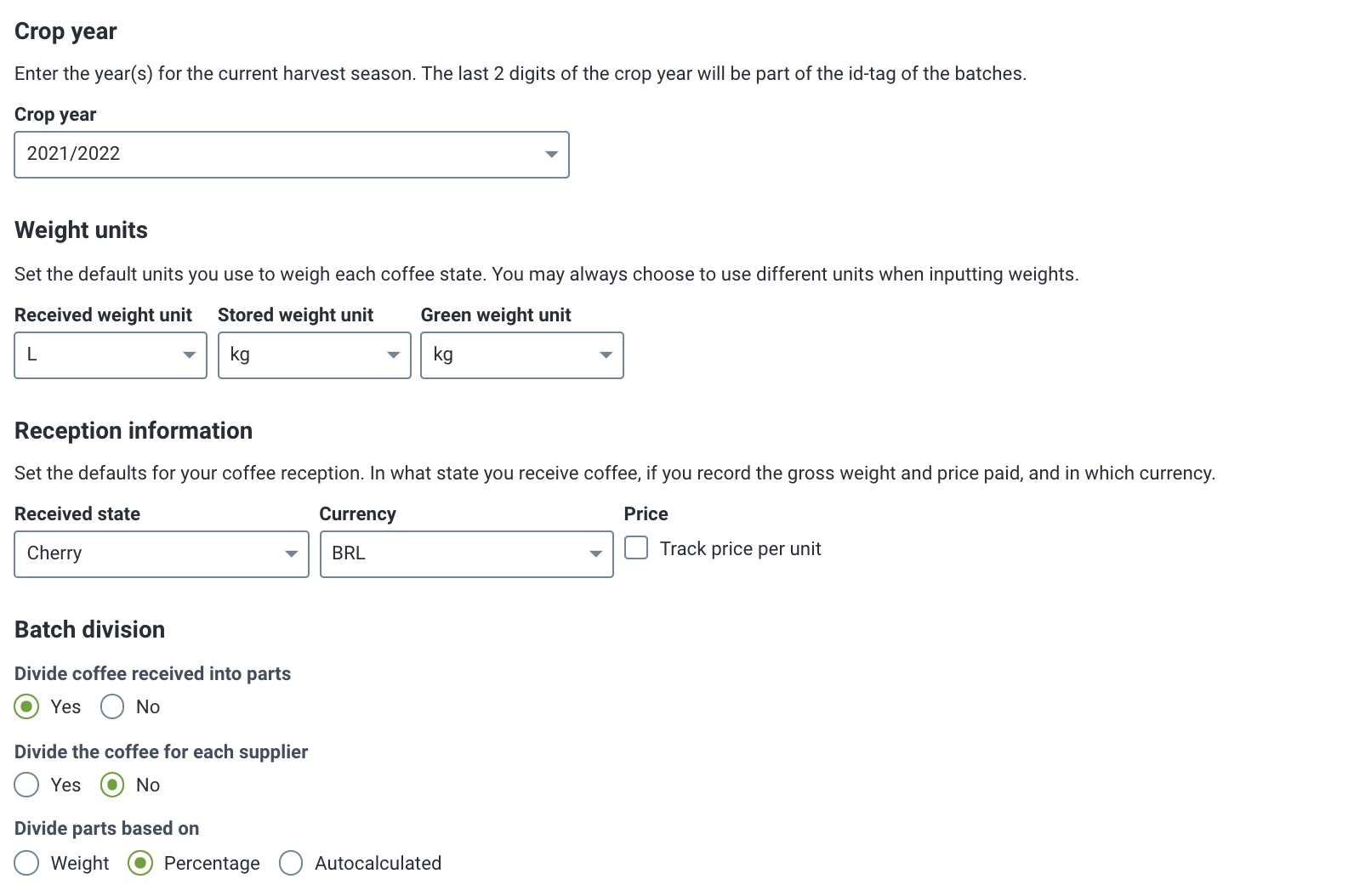

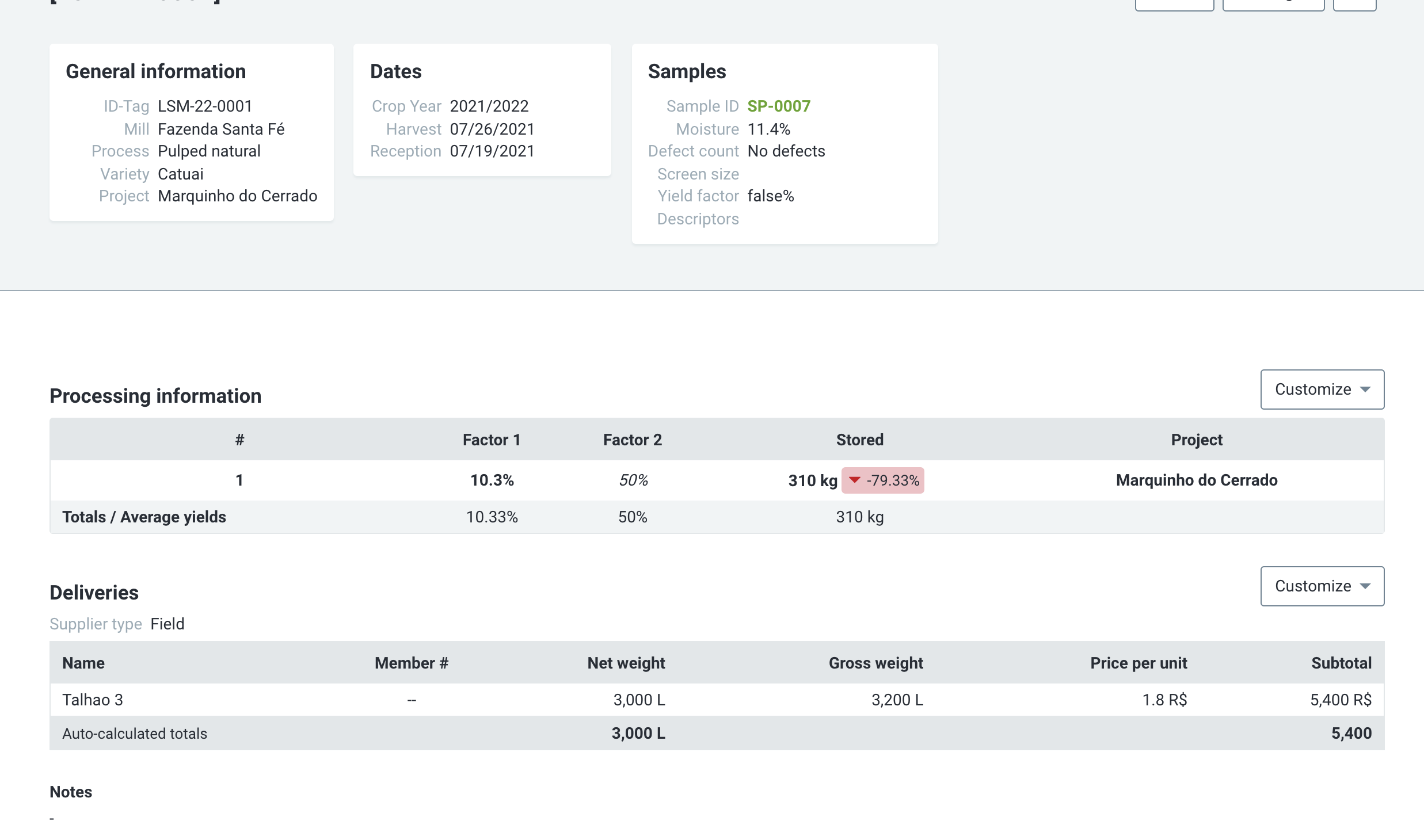

To produce specialty coffees for the first time, I started by controlling my yield factor and the type of measurements I would use to determine the volume produced at each step of processing, as you can see in the image below:

Initial setup for post-harvest data collection.

The Harvest

Using Cropster Origin, I can see how much volume I am harvesting and how much post-process volume I will produce with induced fermentation or natural drying. My first challenge was to calibrate the harvester so that it would only pick the ripest fruits and leave the green ones on the tree. To accomplish this, we removed some teeth from the lower part of the harvesting machine, which harvested more homogeneously ripe cherries.

Harvesting the coffees with Marquinho.

The result of the harvest is what you see in the image below:

Coffees in the floating tank after mechanized harvesting.

Sorting

Because of our modifications to the harvesting equipment, we had a much higher proportion of ripe cherries to green cherries – increasing our yield of high quality coffee. The next sorting step was to pass all the coffees through a floating tank to separate the ripe cherries from floaters, helping us to produce a higher quality coffee. This is a time-intensive process that took a whole day to separate the coffees in just a single lot of Red Catuai cherries.

Livia Mundim monitoring the floating and separation of the coffee.

Yeast Inoculation and Induced Fermentation

After separating the floaters from the ripe cherries, we undertook fermentation. We placed the ripe cherries into 250 kilo bags and sprayed them with Lalcafe ORO yeast with the goal of developing coffee with a slightly more fruity sensory profile. The bags were closed and placed in the shade of trees for 72 hours.

Cherries undergoing induced fermentation in the shade of the trees.

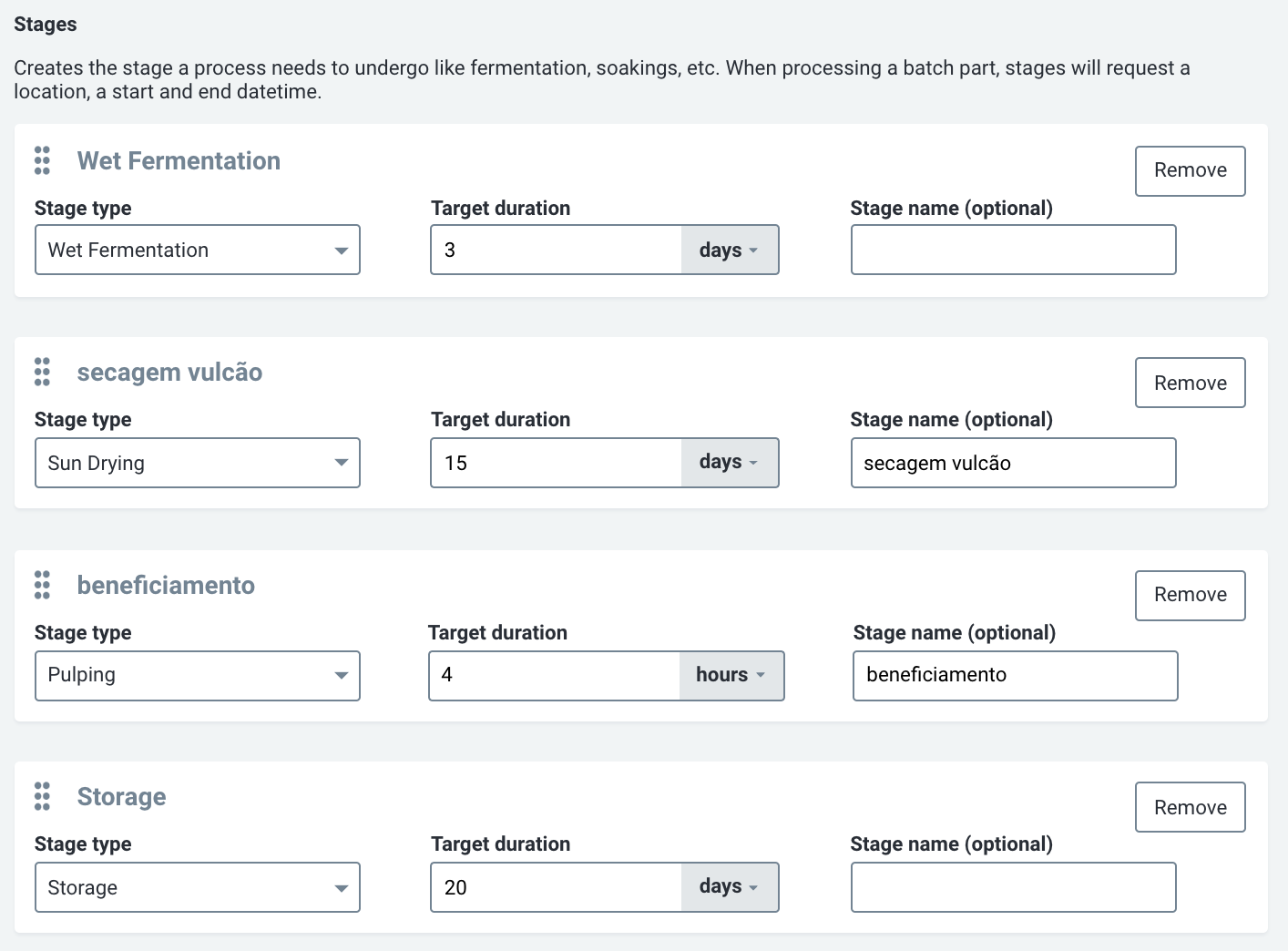

I used Cropster Origin to track every step of production, from harvesting, floating and sorting, fermentation (shown in the image below), and drying. For the first lot, I outlined and followed these steps. Because the steps are customizable, I can create as many steps as necessary, and can add additional data collection including room temperature, humidity, ph, and brix among other data points.

Cropster Origin, stages of the post-harvest process, batch 1.

There is no magic formula for producing exceptional coffee. The quality of the coffee depends on factors that are sometimes out of our control, such as the ambient temperature and humidity. Collecting data, tracking the production steps, and analyzing the results helps me as a producer understand the quality of my coffee, track the results of the steps I undertake, see the impact of elements outside my control, and make necessary adjustments when things don’t go as planned.

Producing Natural and Pulped Natural Coffee

After fermenting for 3 days under the shade trees, we took the next step to process and dry the coffees, taking two different approaches with the harvest. We sent part of the lot to dry as fruit-dried natural coffees. We sent the other lot through a de-pulper to remove the skin and pulp and then dried it as a pulped natural coffee.

We dried the pulped natural coffee for 3 days on the cement patio and then moved it to a raised bed. We kept the natural coffee on the drying patio the entire time and used the volcano drying technique.

Honey coffee drying on the raised drying bed.

Natural coffee drying on the cement patio.

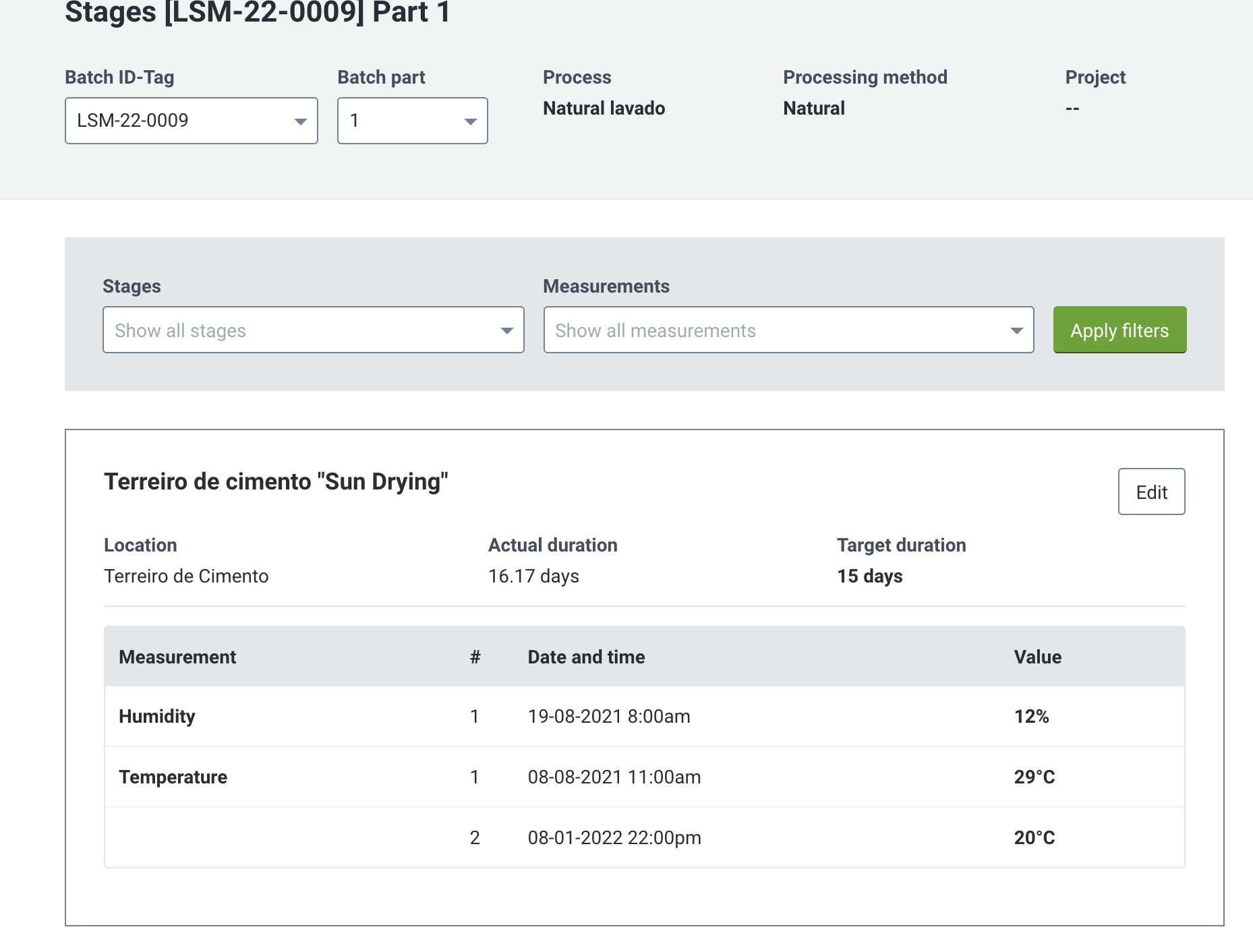

While the coffees were drying on the patios and raised beds, I monitored the temperature and humidity and logged the results in Cropster. I also recorded the number of times we turned the coffees and moved them onto the patios and raised beds.

I didn’t need to be on the farm to track and control the quality of the coffees, as I could instruct my team at the farm on processing steps and track the results through my Cropster Origin account.

Drying monitored by Cropster Origin.

The image above shows that the drying time for this lot was longer than I had foreseen. By also checking the temperature and humidity, I could observe how different environmental conditions affect drying time.

Quality control of coffee samples during drying.

Final Results: Quality, Yield, and Volumes

We produced 8 experimental batches in 2021 with some using anaerobic fermentation and the others using yeast inoculations under the management of Matheus Tinoco. We achieved a significant result with these coffees. This coffee is fruity, medium-bodied, with a notable sweetness; however, the quantity produced was very small.

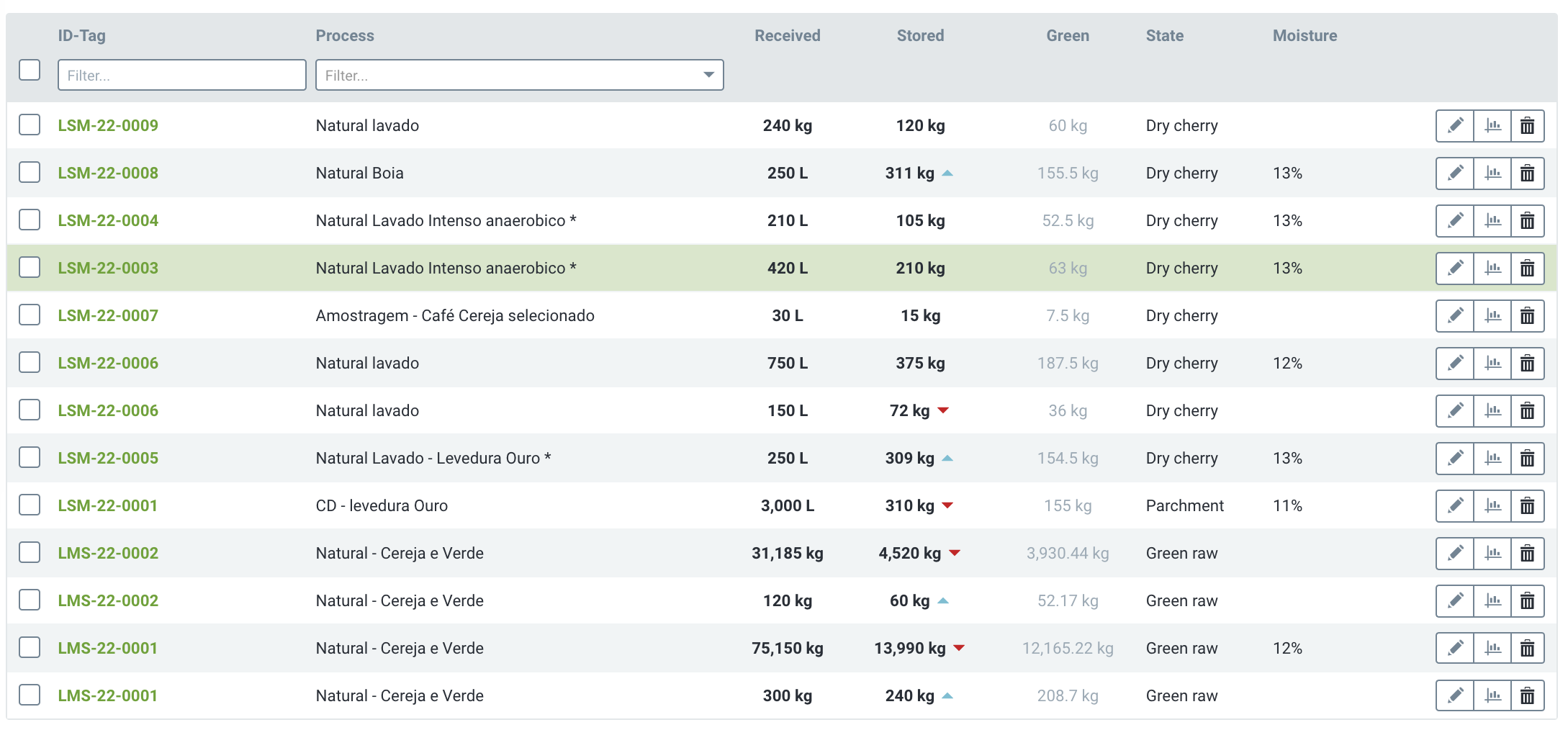

The image below shows how I controlled the yield and volumes of my coffees with estimates beginning at harvest and the final results after drying and milling. I can see which processes result in greater loss in volume and which ones have smaller losses. In case the loss is greater than my estimate, I know exactly what may have happened during the process.

Loads and control of the yield factor of each lot.

Market Access and Roasting

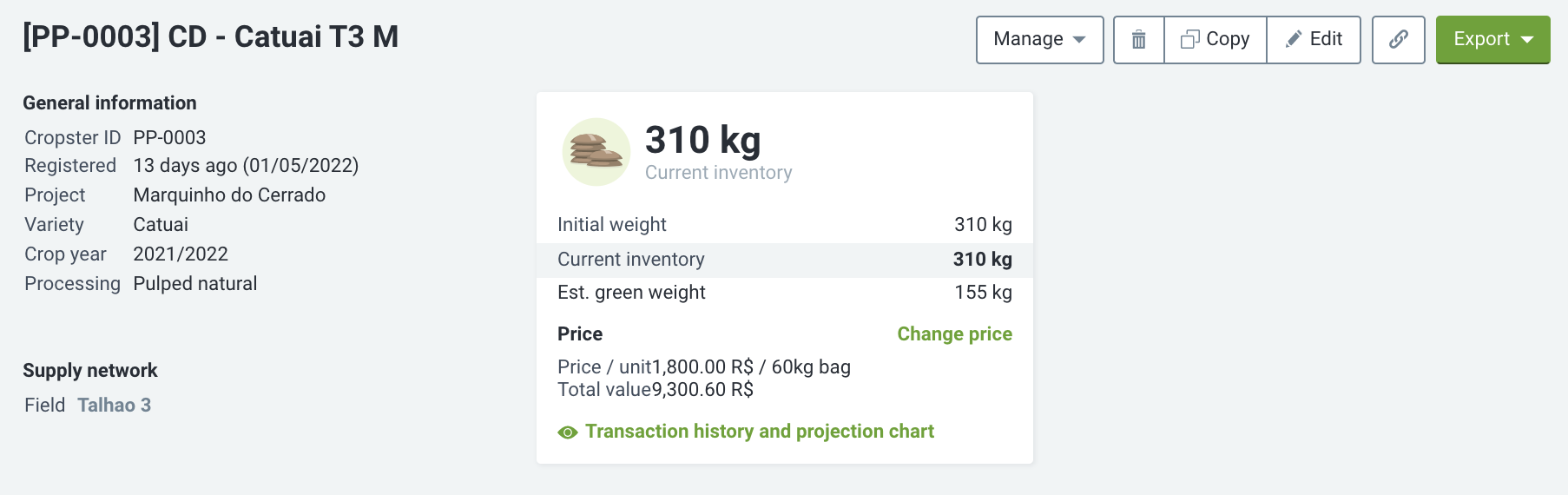

After processing and cleaning, I sent my coffees to a cooperative for resting and storage. In the following image, you can see the post-harvest traceability of my pulped natural coffee sold to Muy Café de Goiânia. This traceability provided by Cropster Origin makes it much easier to guarantee the quality of my coffees to roasters and replicate the results consistently in future years.

Batch of ready green coffee in my stock.

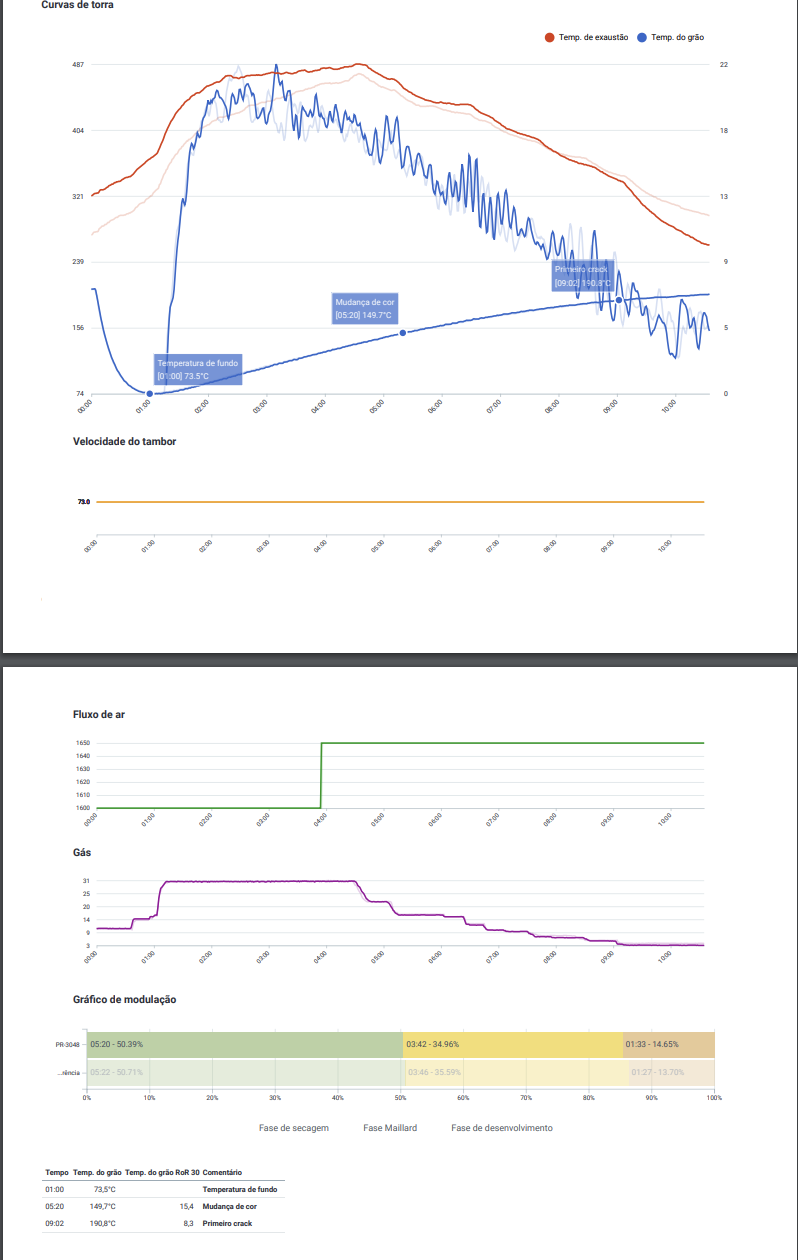

Roast curve Batch CD Fermented, curved and roasted Muy Café.

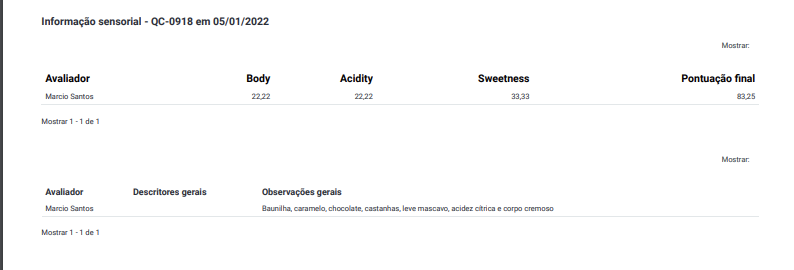

Muy Café also has a Cropster account for roasting and we could share coffee quality information from the farm and the sensory analysis from the roaster, as seen below.

Sensory analysis Muy Café.

Analysis of the Harvest

This was all a trial at producing several micro-lots of specialty coffee. While the volumes are small, the analysis and reports from my 2021 harvest are valuable.

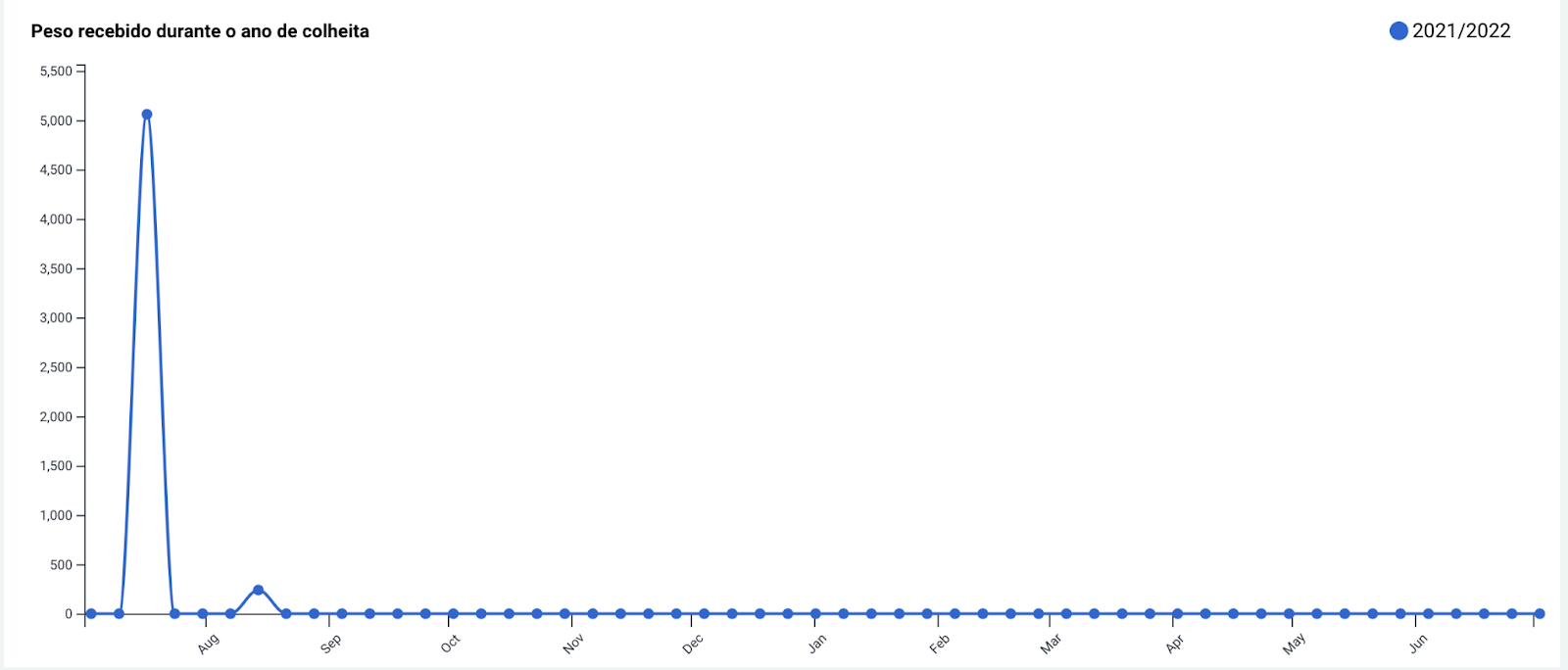

Flowchart of the harvest period on the farm.

In the image above, it is possible to visualize which periods were the most productive during the 2021 harvest on the farm. During the second and third weeks of July, I worked in plot 3, and harvested and processed approximately 5000L of Catuai coffee. I can see from my charts that during August I worked the shaded trees on the farm, which had a later production and lower yields of approximately 500L.

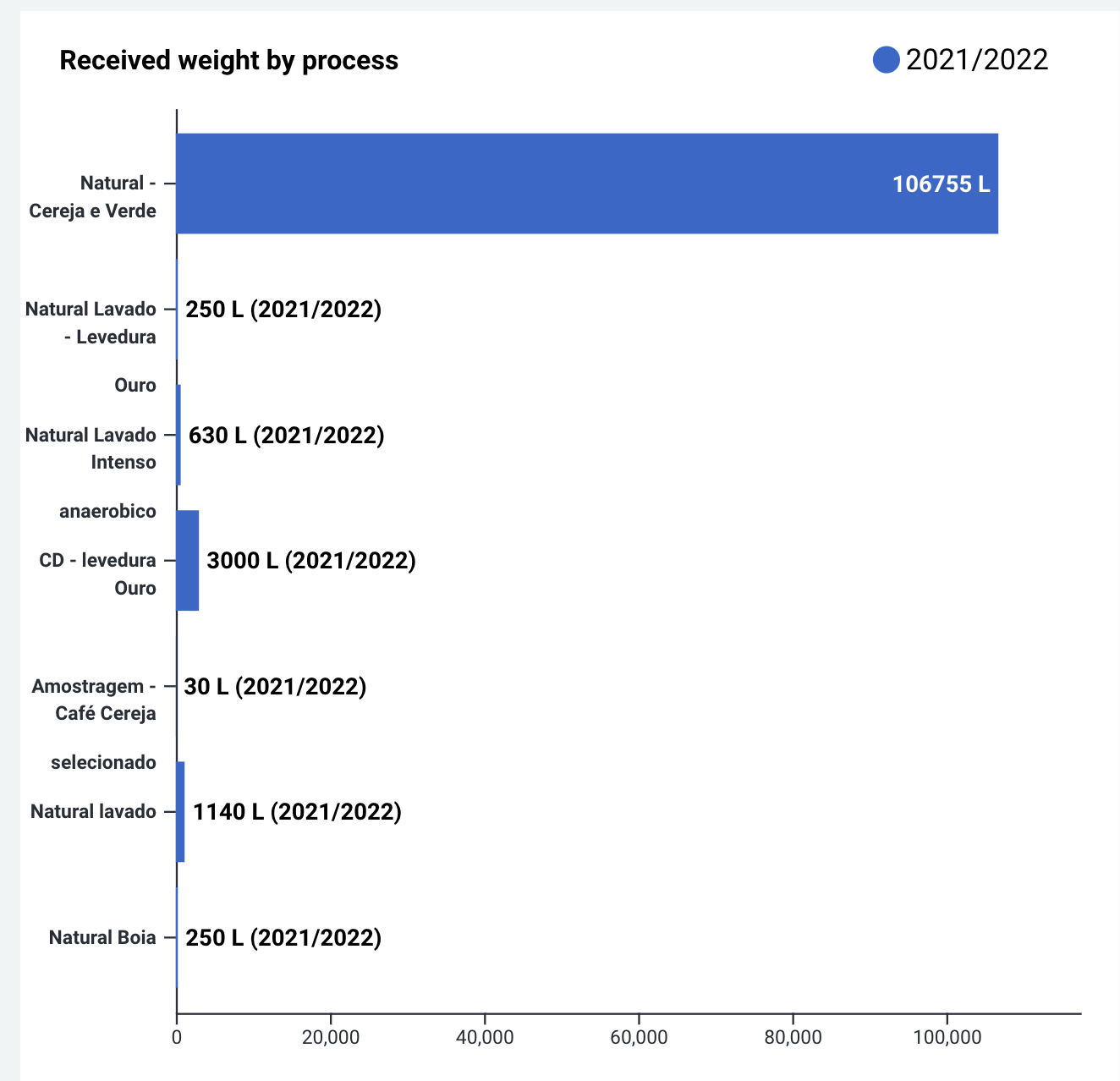

Processes used in the processing of coffee.

The graph above shows the amount produced by processing style. The fermented CD lot produced by Marquinho and his team produced a greater volume of specialty coffees.

Conclusion

I set out in 2021 to invest in specialty coffee at Fazenda Santa Fé da Vereda, my family farm. With Cropster Origin, I could record, track, and monitor the yields from each step of the harvest and processing. Through the season, I saw the benefit of keeping my data organized. I could quickly assess the yields and quality of a variety of processing trials. I could share production and traceability information with roasters, and at the end of the year, I had data on-hand to show me the results of the harvest and provide direction for future trials.

Book at Demo to learn how Cropster Origin can improve the management of your coffee production.