The next big thing in roasting & AI is here – First crack prediction

| RI

Table of Contents

During roasting, the first crack does not always happen when we expect it to. There can be multiple reasons for that, e.g. your starting temperature or environmental conditions (outside temperature) might vary from when you did the reference roast. With the new AI-based First crack prediction these challenges are solved. You can now make adjustments to gas or airflow based on when the first crack will most likely happen.

What is the first crack and why is it important?

The first crack is an important event that happens during the roast. Basically, it is a cracking sound (comparable to popcorn popping) you can hear when the coffee beans have expanded and the moisture has begun to evaporate from the beans. Roast expert and consultant Rob Hoos told us in our RoastID webinar that the first crack is where a significant amount of water starts to evaporate from the coffee beans which allows the heat to penetrate the bean and causes chemical reactions. Studies show that this phase together with coloration has the biggest impact on aroma and flavor development.

To have better control over the roasting and start of the development phase, it’s therefore useful to be ready for the first crack. In our first RoastID webinar we also spoke to roasting experts Anne Cooper and Shelby Williamson who highlighted the importance of making sure the roast doesn’t stall around the stage of first crack (stalling is when not enough heat is applied or gas is cut too early and the Rate of Rise drops too quickly). Overall, a roaster should anticipate when the first crack is happening to control the start of the development phase. With AI based First crack prediction in Cropster, roasters are closer to knowing the “exact” time of first crack.

How does it help my roasting process?

When you roast a completely new coffee, the first crack is often a “guesstimate”. Experience helps a lot, but understanding how a new coffee will react to a gas change requires multiple test batches to achieve your desired outcome (e.g. development time ratio). With First crack prediction you can improve this process and save time and resources as you get to a result faster and with fewer batches.

The prediction was super beneficial when dealing with abnormal batch sizes (i.e. bigger or smaller than standard size), and when creating new roast profiles. It’s a super cool feature.

Katie, Mission Coffee

Plus, dialling in a new roasting machine or training new staff members gets a lot easier too. With First crack prediction, your roasters have a visual tool at hand to prepare for the first crack event and achieve a consistent roast. It helps new staff to understand this key moment is approaching so they can concentrate on managing the actual process instead of estimating it.

I like the idea, similar to curve prediction, that this feature keeps future events front of mind for the roaster. Reminding us that we are working towards time and temperature goals. For training someone I would use the feature, to keep the subject of first crack planning front of mind.

Paul Arnephy, Cafe Lomi

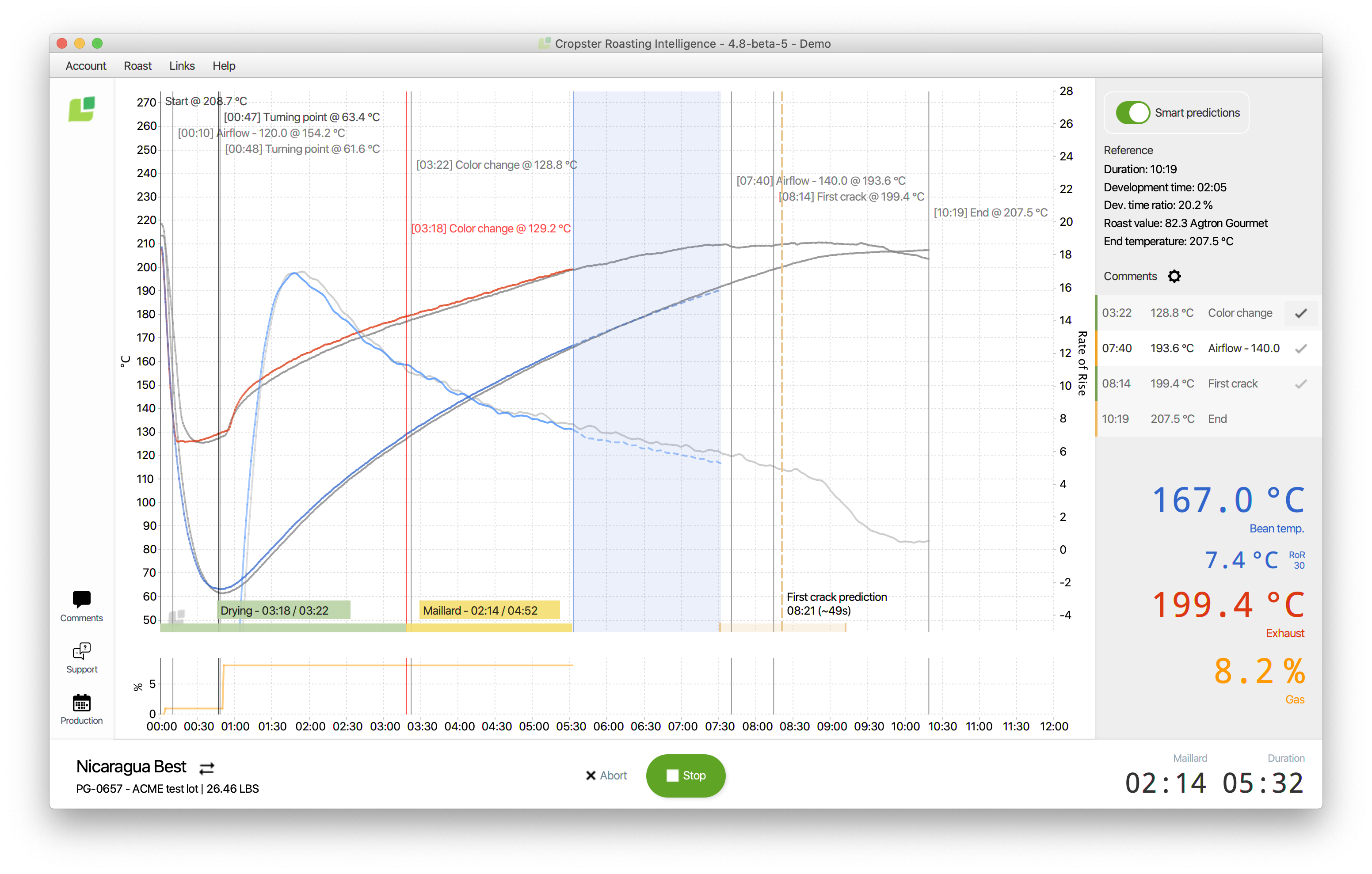

The prediction is shown in the Roasting Intelligence application as a time window and will appear 3 minutes before the first crack is predicted to happen. This means you still have enough time to react and avoid gas or airflow changes too close to the event (as a rule of thumb there should be no gas changes about 40-45 seconds before the first crack and no airflow adjustments 2 minutes before first crack*) to avoid a RoR crash or a flick.

*These times are from Scott Rao’s latest book “Coffee Roasting – best practices”.

AI based First crack prediction will help you adjust your roasting process to control the start of the development phase.

How does it work?

First crack prediction uses applied artificial intelligence (AI) against information collected during roasting. Like AI-powered Bean curve prediction, the Cropster data project laid the groundwork for this new feature. Anonymised data was used to develop a learning algorithm that runs in the background as you roast. Based on its experience, it then predicts a time window when first crack is most likely to occur.

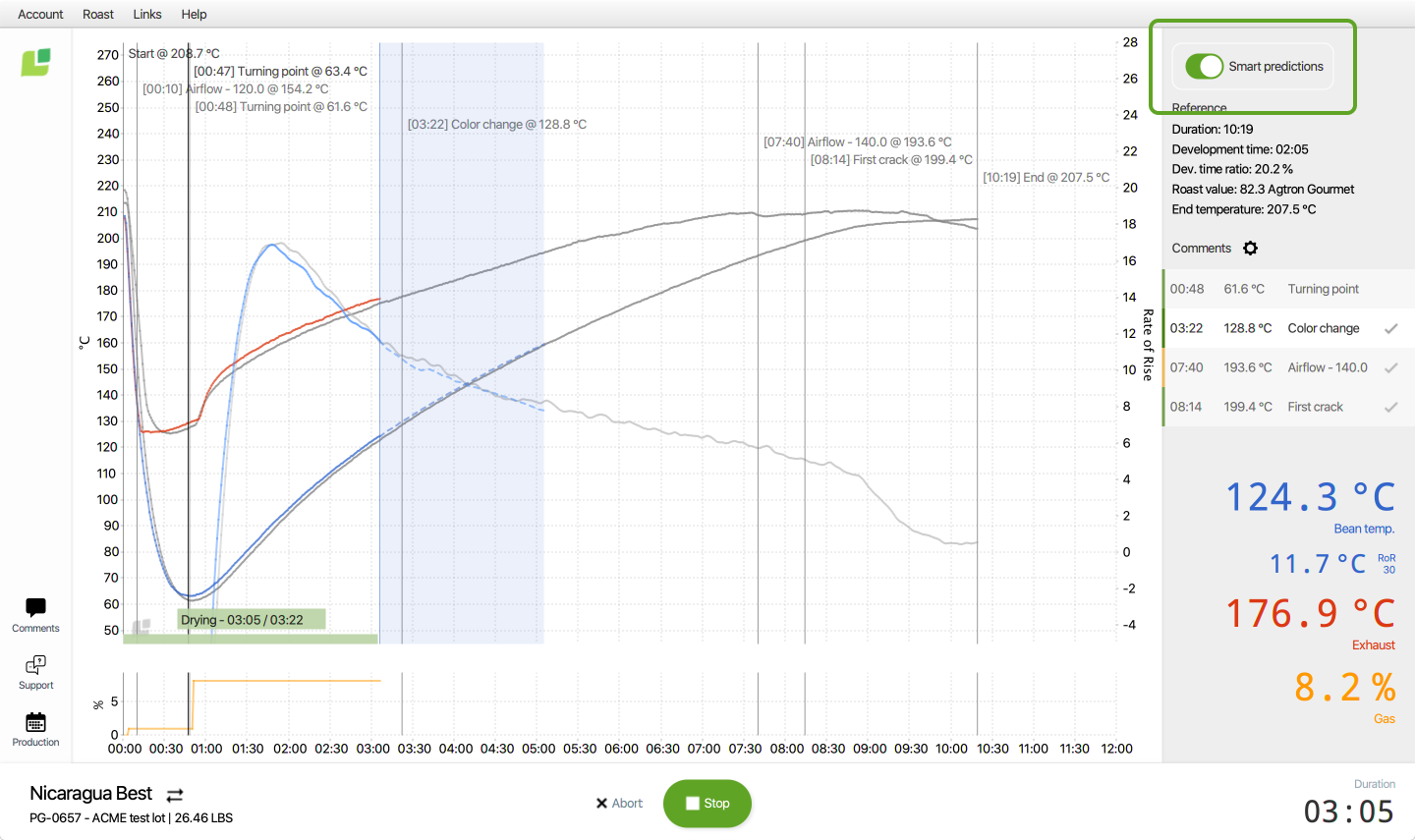

As expected, prediction accuracy depends on many of the same factors that impact roasting itself. The exciting part is that as the algorithm learns, prediction becomes more accurate. It gains insights into your roasting environment. That means it works on any roast machine you can connect to Cropster. Of course, you can also easily toggle it on or off during roasting. We added a “Smart predictions” button to the RI 4 so you can choose to see the AI-powered predictions or not.

You can toggle between showing/hiding the smart predictions in Roasting Intelligence easily.

We’re working on more AI based features to improve your life in the roastery. Stay tuned for more new releases and updates in 2021.

To get started – download the latest version of Roasting Intelligence and read our detailed manuals here.