Kaffee Panel Series – Part 1: Philip Weller

| Lab

Which green coffee did you choose? How did you develop the roast profile? What approach did you pursue to achieve a Q-Grader awarded flavor profile? We asked roasters and participants in the Latin America and Africa editions these and many other questions. We learned a lot and certainly got some very different and interesting answers!

Of course, we know that there is no single universal answer to the question of the best roasting process. Therefore, in this blog series, we will take a closer look at roasting experts and their roast curves to find out more about their respective approaches and strategies.

The working methods and roasting processes of the individual roasters are as different as the roasted green coffee and the roasting machines used. Nevertheless, or perhaps because of this, we believe many roasters can benefit from the experience of these roasters and learn to achieve a top ranking themselves at the next Kaffee Panel!

You can access the complete webinar here: “Cropster & Kaffee Panel 1: Interview with the top roasters live (Africa & Latin America)”. Or read on now to find out more about the results of each roaster.

The roasting experts in this blog series:

- Sebastian Kohrs, elbgold, Hamburg (DE)

- Philip Weller, Günter Coffee Roasters, Freiburg (DE)

- Dario Stoop, Henauer Kaffee, Höri (CH)

- Carsten Wolters, roestbar, Münster (DE)

Additional comments were given on the roasting curves and taste profiles by Philipp Schallberger of Kaffeemacher, Basel (CH). As a Q grader and Kaffee Panel judge, he tasted and rated every coffee himself.

PART 1:

Philip Weller from Günter Coffee Roasters roasts a fermented coffee from Finca El Paraíso in Colombia

Up first is Philip Weller from Günter Coffee Roasters from Freiburg.

Roasting expert: Philip Weller

Roasts at: Günter Coffee Roasters

City / Country: Freiburg / Germany

Roasting machine: Giesen W15A

Green coffee: Castillo, Finca El Paraíso, Colombia, Natural

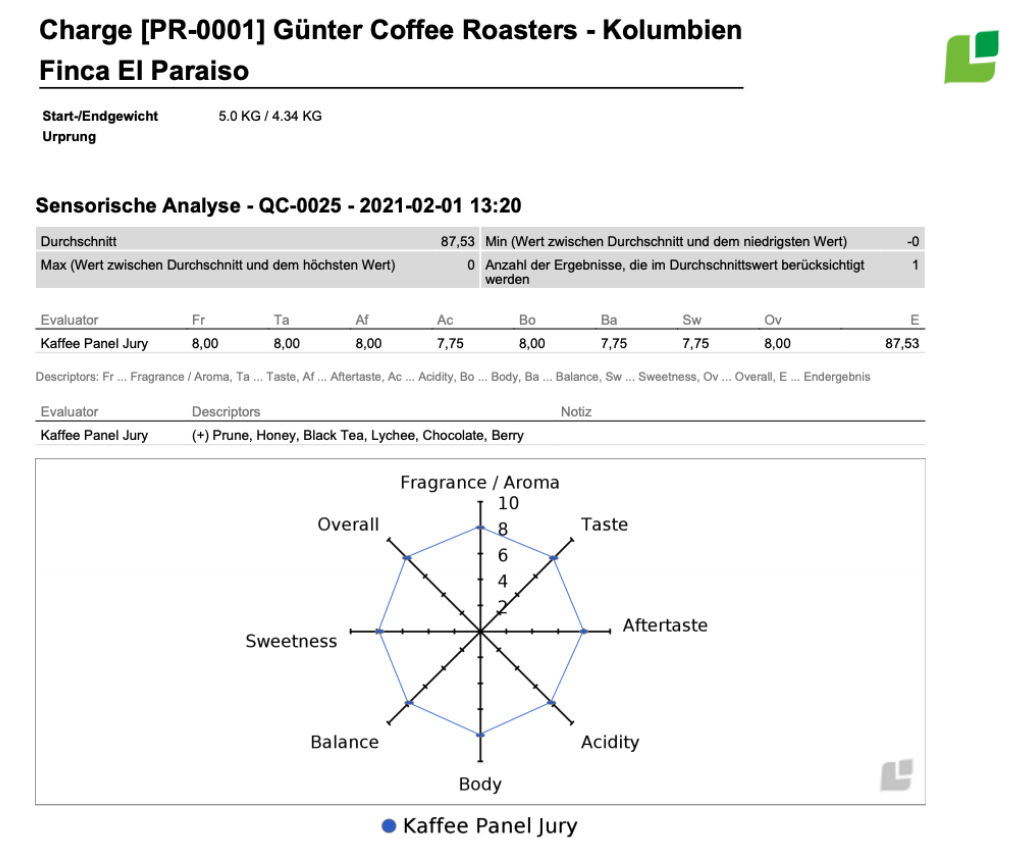

Kaffee Panel Review: 87.53 points

Philip Weller is the founder and head roaster at Günter Roasters in Freiburg. For several years he has been roasting as an autodidactic “roasting punk” on a Giesen W15A. In the Latin American edition of Kaffee Panel, he came in 2nd place in the “various preparation” category with a coffee from Finca El Paraíso in Colombia.

Preparation and selection of the green coffee

When this coffee was harvested, 88% of the cherries were picked when they were fully ripe and 12% were mid-ripe. The coffee then went through an anaerobic fermentation process.. The first phase of the anaerobic fermentation lasted 168 hours. The cherries were then washed and depulped. The second aerobic fermentation phase lasted an additional 48 hours. Finally, the beans were dried in a controlled manner by circulating air at a temperature of 35 ° C and a humidity of 30% until they had a residual moisture content of 10% -11%.

This coffee is not widely popular in Europe because of the heavy fermentation and some very white discolored beans. Philip Weller was brave enough to take a small part of the lot blindly and without tasting.

“Our (moisture) measuring device initially displayed strange things (…) and with the white beans the bean image was pretty ‘wild’. It was not easy to see whether there were any defects.”

Philip Weller – Günter Coffee Roasters

After grading, first sample roasts and tastings, a very complex aroma without defects was formed. The rules of the coffee panel stipulate that the coffee will also be available for purchase in the range later on. The choice for the Latin America edition finally fell on this coffee – which in retrospect proved to be a real stroke of luck!

Approach, goal setting, and profile

Bean size, density and moisture are important characteristics for Philip, which he compares with past roasts in his repertoire. This is how he finds a suitable starting profile.

“Cropster provides good support to choose a profile based on my recorded data that could also roughly match this new coffee.”

Philip finds his first roasting curve for the Giesen W15A from the combination of sample roasts on an Ikawa and comparison with previous roasts. The roast curve he ultimately decides on depends on the taste of the samples.

His aim for this coffee was to embed the distinct fermentation aroma in the taste profile after the first sample roasts and tastings. The fermentation mainly affected the body of the coffee and was very pleasant as an espresso. Building on this, Philip developed an omni-roast from the espresso with a rather light roast, in which he emphasized acidity, fruit and complexity. It can also be drunk as a filter coffee.

Description of the roasting process

The award-winning coffee was roasted with a batch size of 5 kg on a Giesen W15A. Generally, Philip roasts normal batches with a maximum of 12 kg, while smaller or special batches are roasted with 5 kg.

“With 5 kg we have enough leeway and energy reserves to run profiles that are right for us. When we roast at 12 kg, the energy reserves are already very close. That is why we like to roast smaller batches of smaller single origin coffees.”

The roasting curve of the Kaffee Panel Roasting Latin America by Philip Weller, Günter Coffee Roasters

After the roast machine warmed up, roasting started at a temperature of 188 ° C. Immediately afterwards, Philip reduced the gas to 10%. As soon as the coffee had absorbed the energy of the roaster (at approx. 1:35 minutes), Philip increased the gas again to 35%. Based on his experience, Philip Weller with a self-defined, temperature-dependent standard for recording important events such as color change and first crack.

“For me, the subjective timing of the color change and first crack was always a bit imprecise for the comparability between different profiles. We have therefore determined for all coffees to record the color change at 140 ° C and the first crack at 200 ° C.”

That’s why the modulation diagram with a development time of 8% for this roast does not show the real development time from the first crack. However, by standardizing these two points of reference and consequently the roasting phases’ drying phase up to 140 ° C, Maillard phase up to 200 ° C, and the subsequent development phase, it provides a reliable comparison between roasts.

“For me, this enables a comparison between different coffees and roasts. It helps me to better compare coffees of different densities and sizes with different times up to the clues and that has proven to be so useful for me.”

As one can see from the gas recording, Philip gradually reduced the gas starting from a temperature of approx. 130 ° C during the roasting process. After roasting for 10 minutes, he finished the roast at a final temperature of 205.7 ° C.

In general, Philip tries to reproduce the developed reference curve as precisely as possible right from the start. Adjustments are then only made during the course of the year due to weather changes.

“We don’t have air-conditioned rooms and are therefore extremely dependent on the outside temperature. Accordingly, for a coffee that we roast for half a year, for example, we have to clearly adjust the reference four or five times over this period to the changed conditions.”

An important quality control value is a predetermined color range for filter and espresso roasts.

“With us, however, the taste always wins in the end. We taste every batch and continuously incorporate this into the further development of our roasting profiles.”

Analysis and results of the roast

Philipp Schallberger remembered this coffee in particular, as it was very aromatic with many subtle characteristics, lush fruity and heavy floral notes.

“The coffee was incredibly complex and at some point the whole room smelled of this coffee.”

Philipp Schallberger – Die Kaffeemacher

The judges found the exciting thing about this coffee was the aforementioned heavy, soft texture.

“On the one hand, this can be achieved by stretching the middle part of the roast a little, or it suggests that the coffee was very well sorted and that very ripe cherries were used. The sweetness of the cherries is then transformed into this soft texture. That was certainly the case with this light roast.”

The result of the tasting of the Latin American Kaffee Panel jury for Günter Coffee Roasters

“During the cupping, the attributes and intensity of the aromas were a little easier than if we brewed this coffee as a filter. But the result was very transparent and complex.”

Returning to the preparation of this coffee with 88% ripe and 12% medium-ripe cherries, Philipp Schallberger suspects that the proportion of medium-ripe cherries provides the necessary acidity in the coffee and thus complements the luscious sweetness of the fully ripe cherries.

“You noticed that here, there are very lush aromas, with a less complex but very clear acidity.”

We’d like to extend our thanks to Philip Weller and Philipp Schallberger for the exciting insights into the selection of green coffee and the roasting process and the willingness to share your analysis and assessment with us.

In the next article in this series we will introduce another roaster and their roast for the Kaffee Panel.

You can watch the entire webinar on the Cropster website: “Cropster & Kaffee Panel 1: Interview with the Top Roasters Live (Africa & Latin America)”.

For more information on the Kaffee Panel and the announcement of the editions and placements, visit https://kaffee-panel.org/ or the coffee makers’ YouTube channel.