New release: Between Batch Protocol, a key to consistent roasts

| RI

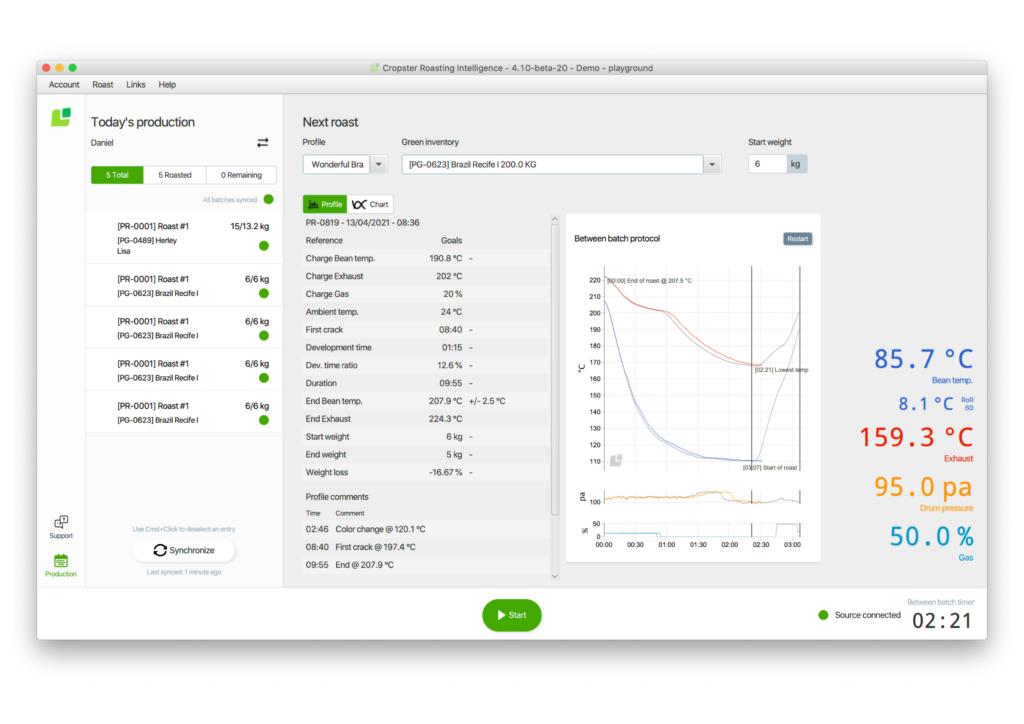

How? By presenting roasters with the information they need to ensure the thermal energy in their roast machine is consistent across batches.

“If customers ask why a profile does not match, when they roast, one of the first things I ask is if they have followed the same between batch protocol. If the starting conditions for a roast are not the same, you won’t be able to reproduce it.”

Anne Cooper – Equilibrium Master Roasters

Between batch protocol helps coffee roasters stay on top of thermal energy throughout production to deliver more consistent roasts for every batch.

What is between batch protocol? Between batch protocol is the process of resetting the thermal energy in your roast machine from the last batch to the start of the next batch. The goal is simple, to arrive at the exact same starting conditions you had for the last batch. As a roaster, your ultimate goal is to create consistency with your approach and product. Without a consistent between batch protocol, you can approach a coffee with the same in-roast strategy as the last batch but without the same initial thermal conditions. That means you are unlikely to replicate your desired roast and create consistency amongst your roasts throughout the day.

“With an effective BBP, one can roast numerous consecutive batches of a coffee using identical gas settings to replicate roast curves and cupping results nearly perfectly. In my experience, most roasters’ batches get faster as a roast day progresses, which means they need to improve their BBPs.”

Scott Rao – Coffee Roasting – Best Practices

When asked specifically about Cropster’s new BBP features Scott Rao, the man who originally coined the phrase “Between Batch Protocol”, told us “I think that the feature will help roasters better predict the paths of the curves, and produce more consistent coffee as a result”.

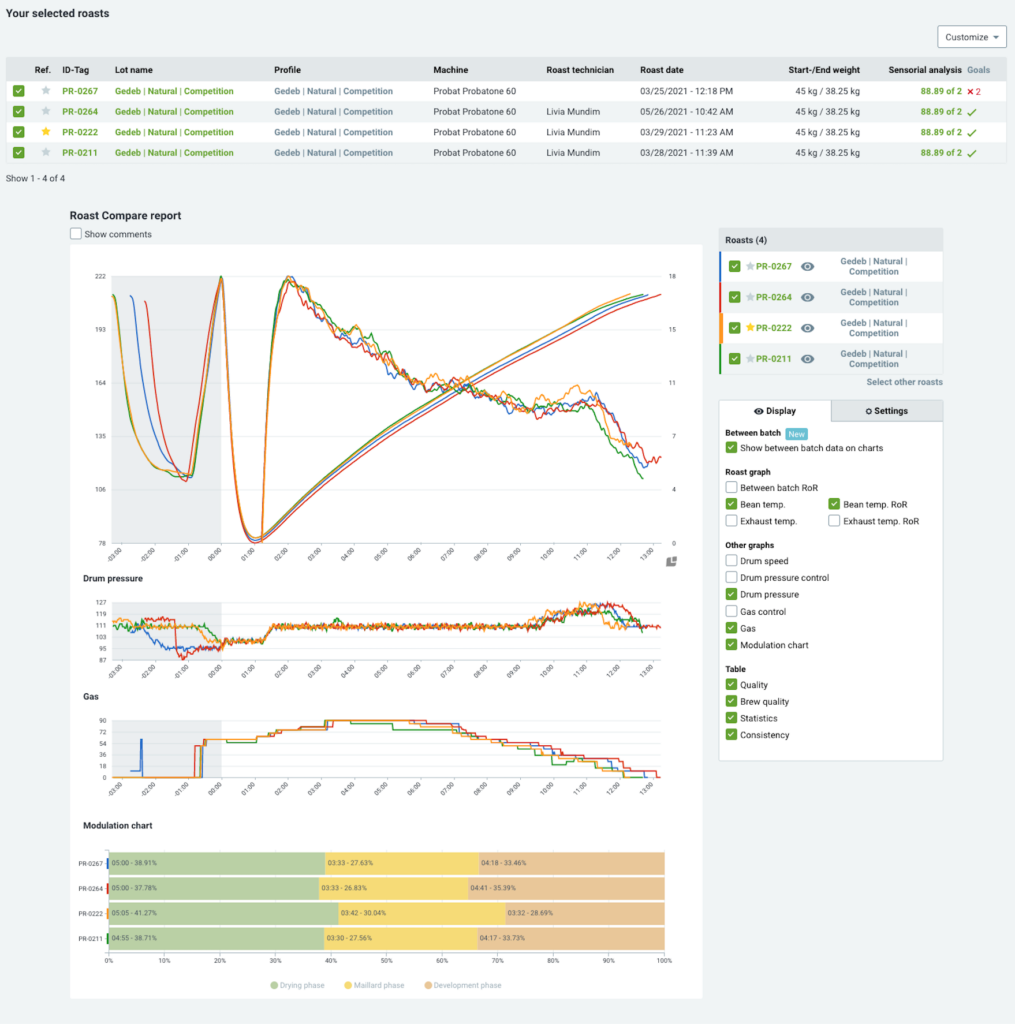

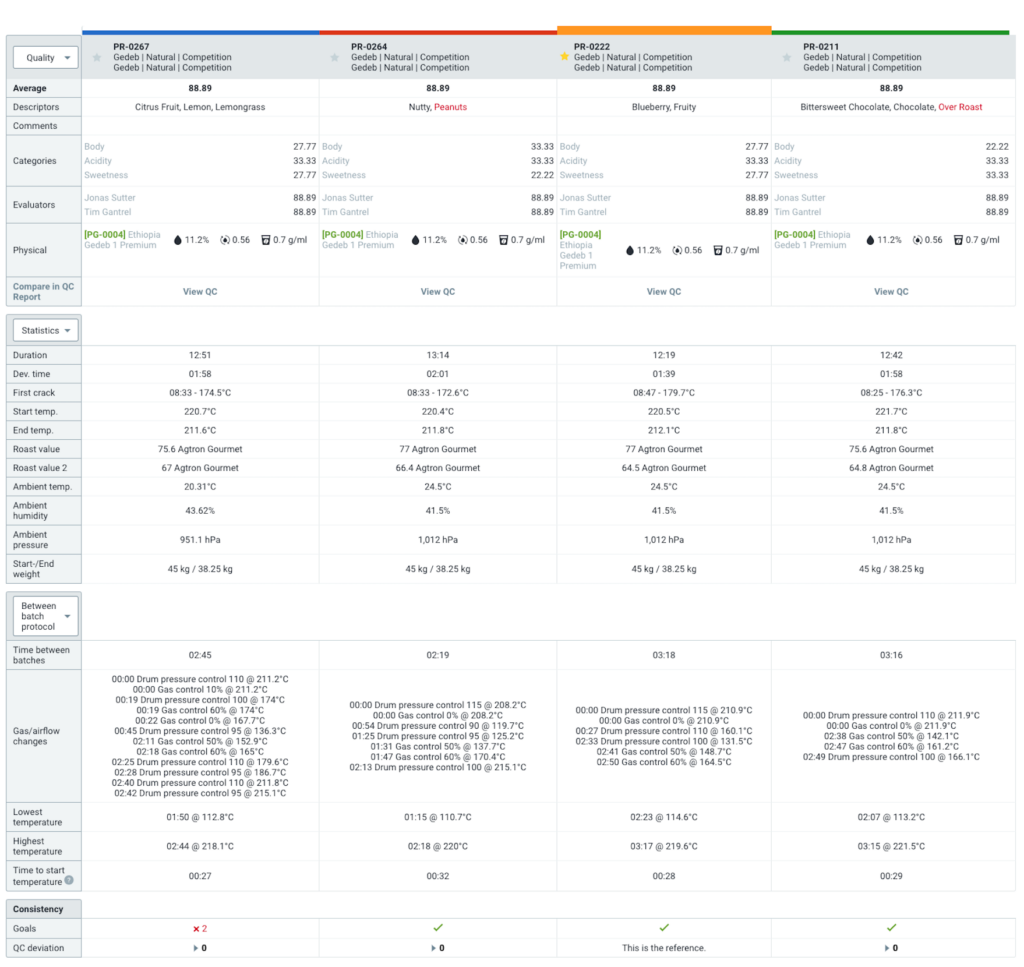

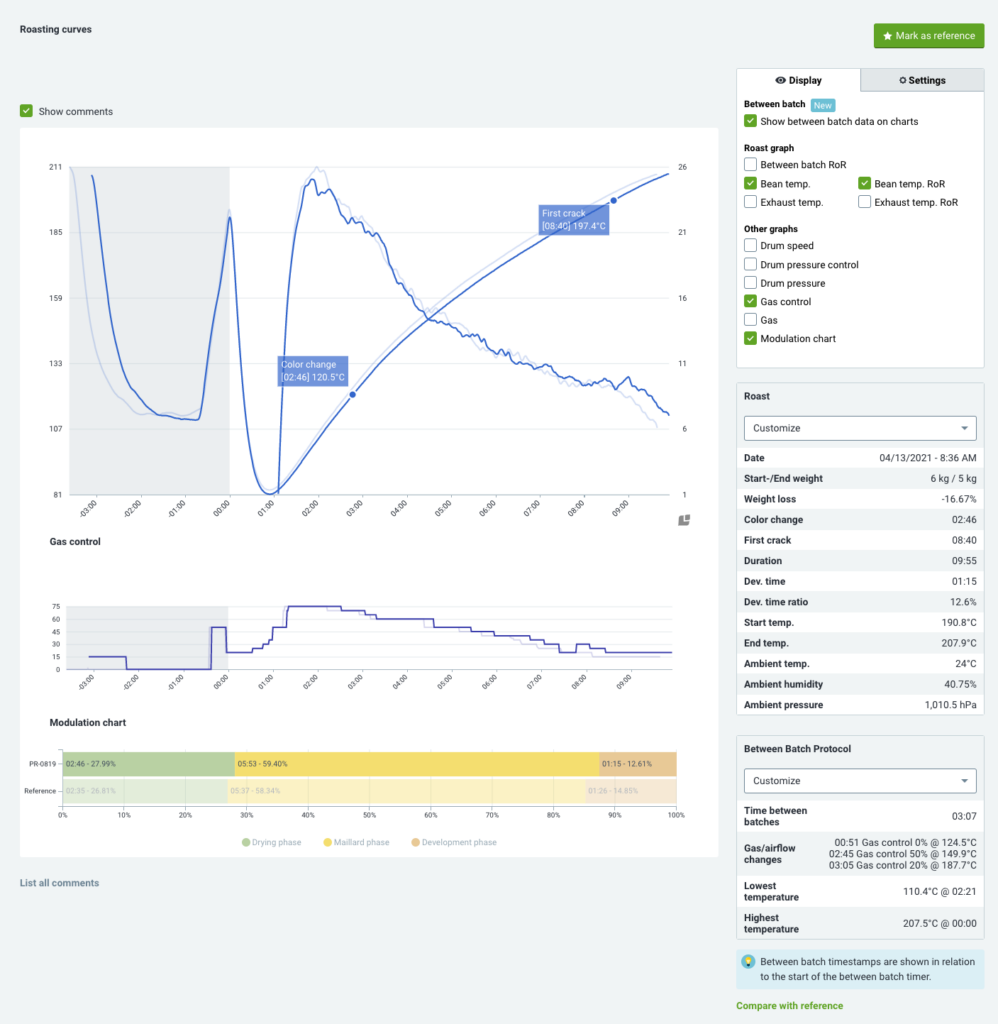

The new between batch protocol update also ties into the roast compare reporting so they can also compare between batch protocol information to further optimize roasts.

With this latest innovation, Cropster delivers a simple way for roasters to record their machine’s temperatures in between batches. That means they can use this information to adjust as needed before the official “start” of each roast to ensure the alignment of pre-roast machine temperatures and energy. An important feature to highlight is that this helps between batches of the same coffee and between batches of different coffees!

“Between batch protocols are definitely important. The biggest reason is to keep the starting conditions for each roast as close to the profile as possible. The more variables are consistent between the roasts, the more consistent they will be. Between batch protocols should help set you up for success.”

Rob Hoos – Rob Hoos Coffee Consulting

As Rob mentions, the more variables are held consistent, the more likely you are to create a consistent product. These variables however are not just restricted to the roast machine’s data and temperatures but also the room’s conditions!

With our between batch protocol feature, Cropster makes this critical thermal information available to roasters and includes the tools they need to act on this information and as a result roast more consistently. It’s available today. All roasters need to do is go to their preferences and make sure the option is toggled on! Some roasters are already using it and loving it:

“Stabilising and preparing the roasting drum for your next batch in sequence is such a crucial part to achieving profile replication. Cropster’s new BBP system has genuinely delivered us with a substantial improvement in the overall consistency of profile replications.”

Ryan – Specialty Batch

”Well, basically the BBP is really a great help and we’re getting much more consistent roasts. It’s great to see „where we are“ between the batches and „what we did“ last time.

Matthias – Gscheid Haferl Kaffeerösterei

“It is great to see the curve and be able to anticipate on it.” “It is easy to see when we have missed the starting point (too high temp) and see what we actually need to do to get back on track again.”

Onno – Stooker Specialty Coffee

If you’re looking to roast more consistently and would like a demo of this new feature or to try it yourself, please let us know. We’d love to show you how.