Ensuring Quality at Wholesale Accounts

| Roast

Written by Matthew Brown

Table of Contents

Many aspiring café owners assume that coffee is a relatively simple business. That if they buy quality coffee from a good brand whose vision and values align with theirs, they’re guaranteed to have at least a baseline quality output, and the customers and financial success will come along soon after. But the truth is, serving a good cup of coffee isn’t just about what beans you start with. It takes the right equipment, the right water, and the right training in order to produce a result that will be beneficial for both the retailer and the wholesale roaster.

If that sounds like a lot, it is. Achieving quality and maintaining it consistently takes commitment. Many of your wholesale customers might not realize exactly how much work they’re really in for, leading to a slip in quality over time. For the sake of your business and theirs, you need a way to monitor quality and provide assistance or correction. That can be challenging if you’re not able to be there in person every day or every week.

There’s an app for that

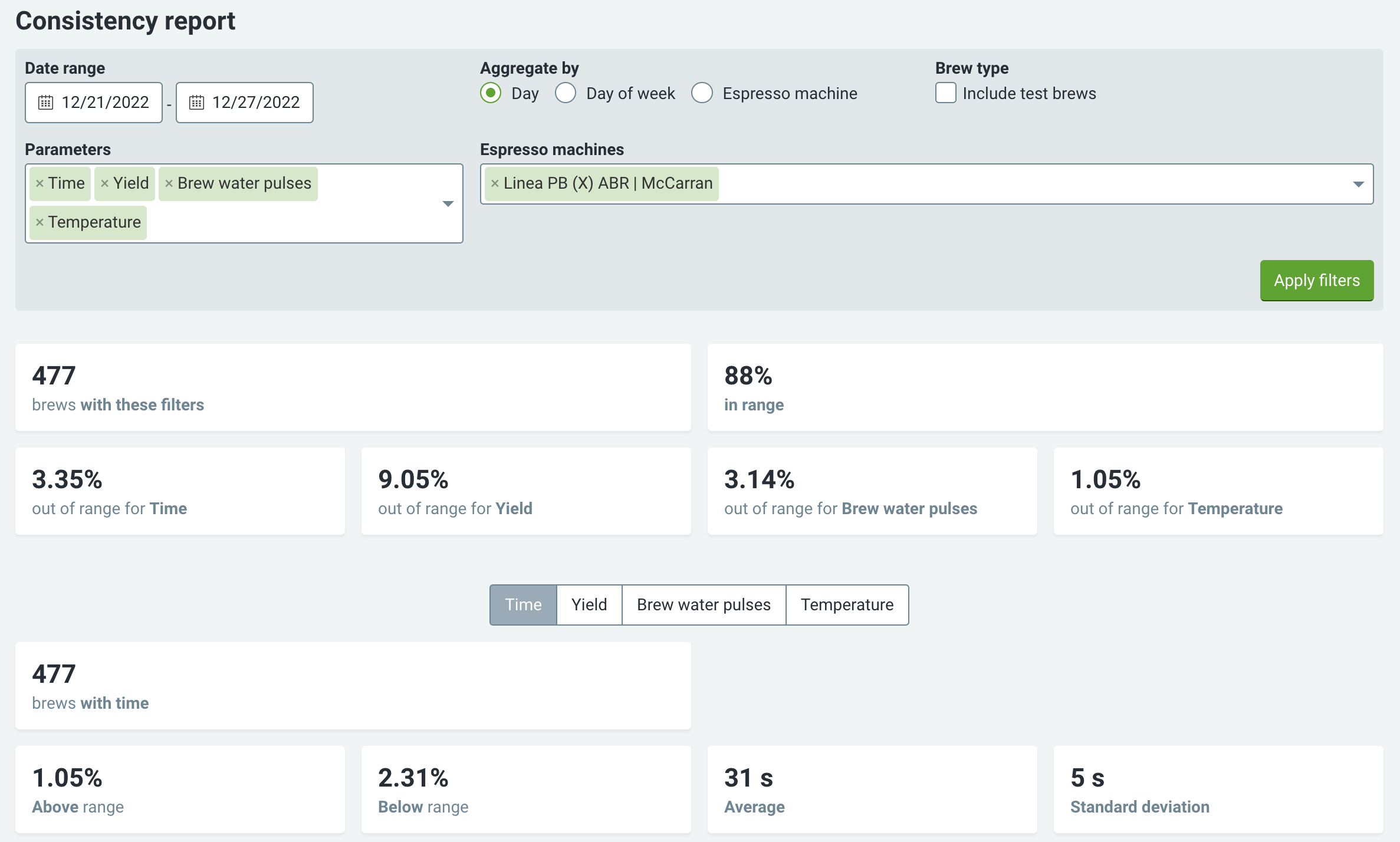

Enter Cropster Cafe. This Cropster software integrates with many La Marzocco espresso machines (connectivity to other machines is coming soon) to provide real-time data on each extraction, as well as water hardness feeding into the machine. It also provides a convenient place to record brew recipes and notes, so even a large team of baristas can always be on the same page.

This is a dream come true for a wholesaler like Coffeebar. When we set up a new account, we’ll help them identify their desired flavor profile and set a recipe standard accordingly. Then we can use Cropster Cafe to monitor consistency each day. This means we can identify issues and respond to them much sooner, and because of the types of data Cropster gets from the espresso machine, we can often diagnose the cause of any inconsistency.

There are five types of data automatically collected by the Cropster Cafe integration with La Marzocco machines:

- The water’s hardness going into the machine

- Beverage weight

- Water pulses

- Brew time

- Brewing temperature

Each one gives us clues as to what’s going on in the café. Here’s a rundown of how we apply each data point:

Water hardness of water going into the machine

Measuring the Water total hardness going into a given espresso machine can provide important warning flags both for product quality and equipment health. Though water hardness doesn’t tell you what is in the water, a large fluctuation will indicate that something has changed. Knowing this, you can help your customer adjust their espresso recipe to ensure they’re still serving nice-tasting coffee, and follow up with additional water testing to identify if there is any potential for damage to their equipment from poor water quality.

Cafes are at the mercy of the local water supply, which will often fluctuate seasonally or change due to things like heavy amounts of construction. If you notice a big swing in the water hardness reported by Cropster, you can also follow up with the municipal water authority to determine if you need to take any additional action (like changing water filtration systems in an RO system) is necessary.

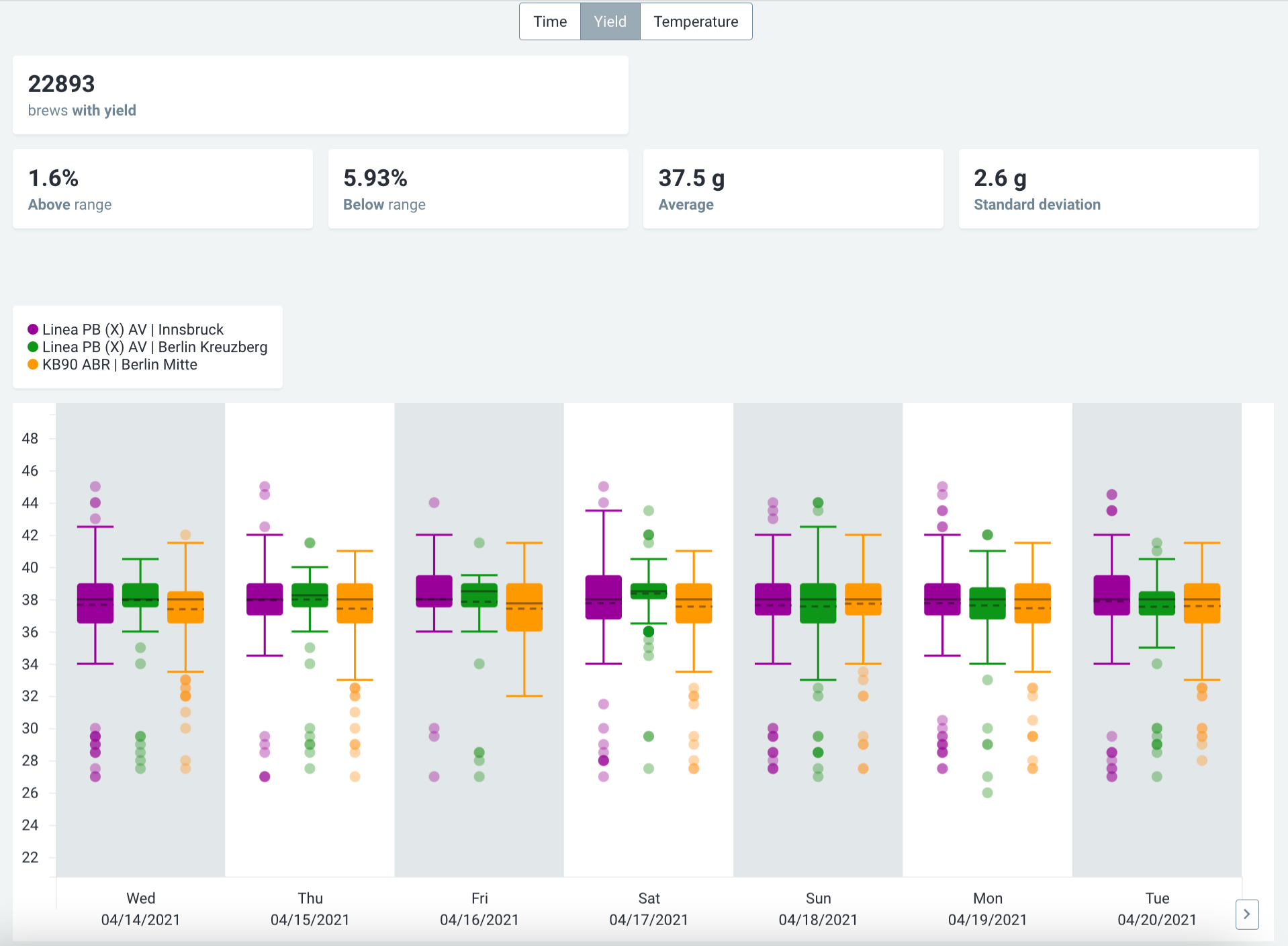

Beverage weight (shown as volume in Cropster Cafe)

If your customer has a La Marzocco model with integrated scales, you can set your desired beverage volume as part of the recipe in Cropster. The scales are remarkably accurate, so if you notice any big swings in beverage weight over the course of time, it could be an indication that the scales need to be repaired or recalibrated. Or that someone was mucking about in the settings. It can also indicate that baristas need additional training in how to prepare espresso according to the cafe’s standards.

Water Pulses

If the scales aren’t present, fear not! The La Marzocco espresso machine can measure electrical pulses via the flow meter. These pulses also translate into a volume measurement to show the consistency of your brews. Having both the beverage weight AND the pulses on at the same time will allow you to see if one or the other device needs calibration or service, or identify specific training opportunities for bar staff.

Brew time

The brew time for any given shot will be determined by the coffee dose, grind, distribution, and compaction, which means it’s a good indication of the attentiveness and skill of the barista. Large inconsistencies in brew times will often point to a need for additional training, or could indicate that the espresso grinders need servicing, cleaning, or calibration.

Brew temperature

All La Marzocco espresso machines have brew boilers that are separate from the steam boiler, which provides good thermal stability. You will still have some temperature variation as hot water flows out of the boiler and cold water flows in. If you notice large fluctuations in brew temperature, the most likely culprit is a barista using their groups to rinse portafilters, thus draining the brew boiler and causing a large influx of cold water. It could also be an indication of a heating element that is likely to fail, or a boiler that requires descaling or other maintenance. Once again, Cropster data identifies a need for follow-up training or repair to the heating system.

Combining data with sensory – finding seasonal variations

What we can’t see with this data is how the coffee tastes, only how consistent it is. Even though we worked with our clients to set a recipe, coffee changes as it ages, and through the seasonality of your blends. Having Baristas input tasting notes along with how they have tweaked the recipes every day allows a roaster to see how the flavor of your product varies from one wholesale account to the next, and what each cafe has to do to adapt to these environmental changes. Similarly, as a roaster you can enter tasting notes for a specific brew recipe, providing cafe’s with a target flavor reference while dialing in.

All in on Automation

One of the things all this Cropster Cafe data tells you is that consistency is really difficult to achieve. Even supporting your wholesale account with good training and high-quality products, quality and consistency will often falter when the cafe is particularly busy, or short staffed, or getting stared down by an under-caffeinated and impatient guest. Baristas will often choose speed over attention to detail. The good news is that there are an increasing number of automated technologies available to help your baristas be more efficient and more consistent in their espresso preparation.

Automated tampers compact coffee consistently regardless of who is working and help reduce the risk of repetitive stress injuries. Automated milk steamers provide perfectly textured milk at exactly the right temperature. Espresso machines with scales and/or volumetric controls and grind-by-weight grinders make it easier to execute your brew recipe accurately for every shot.

When you combine skillful baristas who are tasting and making adjustments throughout service with these technologies in conjunction with Cropster Cafe to keep an eye on recipe alignment, you can achieve the dream: not just being consistent, but being consistently good.

The Takeaway

Automation helps ensure consistency for happy customers and at the same time reduce repetitive tasks, guess work, and stress injuries for baristas. Adding in Cropster Cafe gives you data-driven insight so you can be proactive about both training and equipment maintenance with your wholesale accounts – no matter where they’re located. As brilliant as all this new technology is though, it’s important to remember that great quality comes from good training. To really make the most of Cropster Cafe’s data you need someone who can taste the coffee and provide feedback and make adjustments based on flavor, otherwise you’ll be missing crucial context you need to provide support.

But when you integrate Cropster Café and key automated technologies into your wholesale program alongside hands-on training and support, you’re giving yourself and your partners the best possible chance at success and protecting the integrity of both brands.

Matthew Brown is the Manager of Coffee operations at CoffeeBar, a roastery and coffee retailer with 9 locations based in Reno, NV; Truckee, CA; and in the San Francisco Bay Area USA. Matthew started his career in Australia nearly twenty years ago, and applies his experience to CoffeeBar and as an Authorized SCA, and Barista Hustle coffee educator. He focuses on building quality standards with an eye for the technical aspects of brewing techniques, brewing equipment, water quality, and more. In the following article, he shares his expertise in brewing for consistency and ideas about Cropster Cafe’s role in managing quality across multiple locations.