How Cropster connects to YOUR roast machine

| Roast

Written by Andy Benedikter, Devin Connolly

Table of Contents

Over 50 countries worldwide are running Cropster Roasting Intelligence (RI) in their roasteries. This is a testament to the general ease of connecting any roaster to our software. If you can roast with it, you can use Cropster with it.

Here is a short extract of roast machines that we have connected to Cropster already:

Giesen – Loring – Diedrich – Probat – Coffeetool – Proaster -San Franciscan – Bühler – Toper – Has Garanti – Atilla – Garanti – Petroncini – Joper – US Roasters – Gothot – Ambex – STA – Renegade – Brambati – Huky – Quest – Coffee Tech – Roastmax – Victoria – Bella Taiwan…

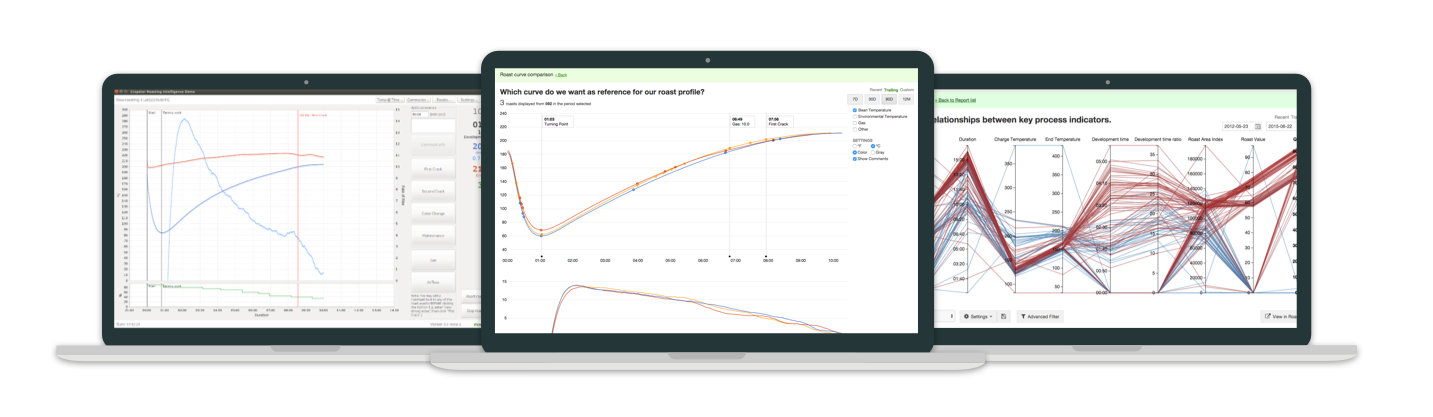

We would like to share with you the two ways that people can connect to our software to enjoy our roast profiling, comparison, QC, production and inventory tracking tools.

Method One: Plug & play via PLC

Cropster provides no-hardware, plug&play solutions for the following roast machines:

- Loring Smart Roasters

- WxxA Giesen Coffee-Roasters built after June 2014 (ex. W15A)

- Coffee Tool Roasters with a PLC

These machines do not require anything more than an ethernet cable. We simply connect to the machine’s computing unit (PLC). Setting up these machines take less time than it does to warm up your roaster. If you have one of these roasters and want to try our software we can set you up without a hitch.

These setups are very easy and offer even more data to log, analyze and integrate. Since they connect directly to your roaster’s computer, they not only track temperatures, but – depending on the machine – gas flow, burner percentage, afterburner, environmental temp, rotation of the drum and more.

Most new roasting machines have a PLC. You might now be wondering if you could integrate a machine that has a PLC but isn’t on the list. The answer is not right now, but there is potential. Integration with each interested roasting machine manufacturer is on our road map. To speed up this process, feel free to write your manufacturer and tell them they need to integrate with Cropster out of the box through their PLC/PID! We would love to partner with them and it will make the setup even easier for you.

Method Two: Via Cropster databridge

Don’t worry if your machine isn’t listed above. Cropster can integrate with any other roaster that has ungrounded thermocouples (K, J, E or T type) or RTD temperature sensors. This is the case for 99% of the roast machines we know of. The Cropster databridge can handle up to four temperatures at the same time, which means either one production roaster or multiple barrels on a sample roaster can be tracked at the same time. Connecting your roaster to our databridge is usually a matter of 30 minutes or less.

Here is a little bit of information on each type of setup.

A) Ungrounded Thermocouples: K, J, E and T

The vast majority of drum roasters use K or J type thermocouples, with ungrounded K types in the lead. Both new Diedrich and new Probat machines use this as standard.

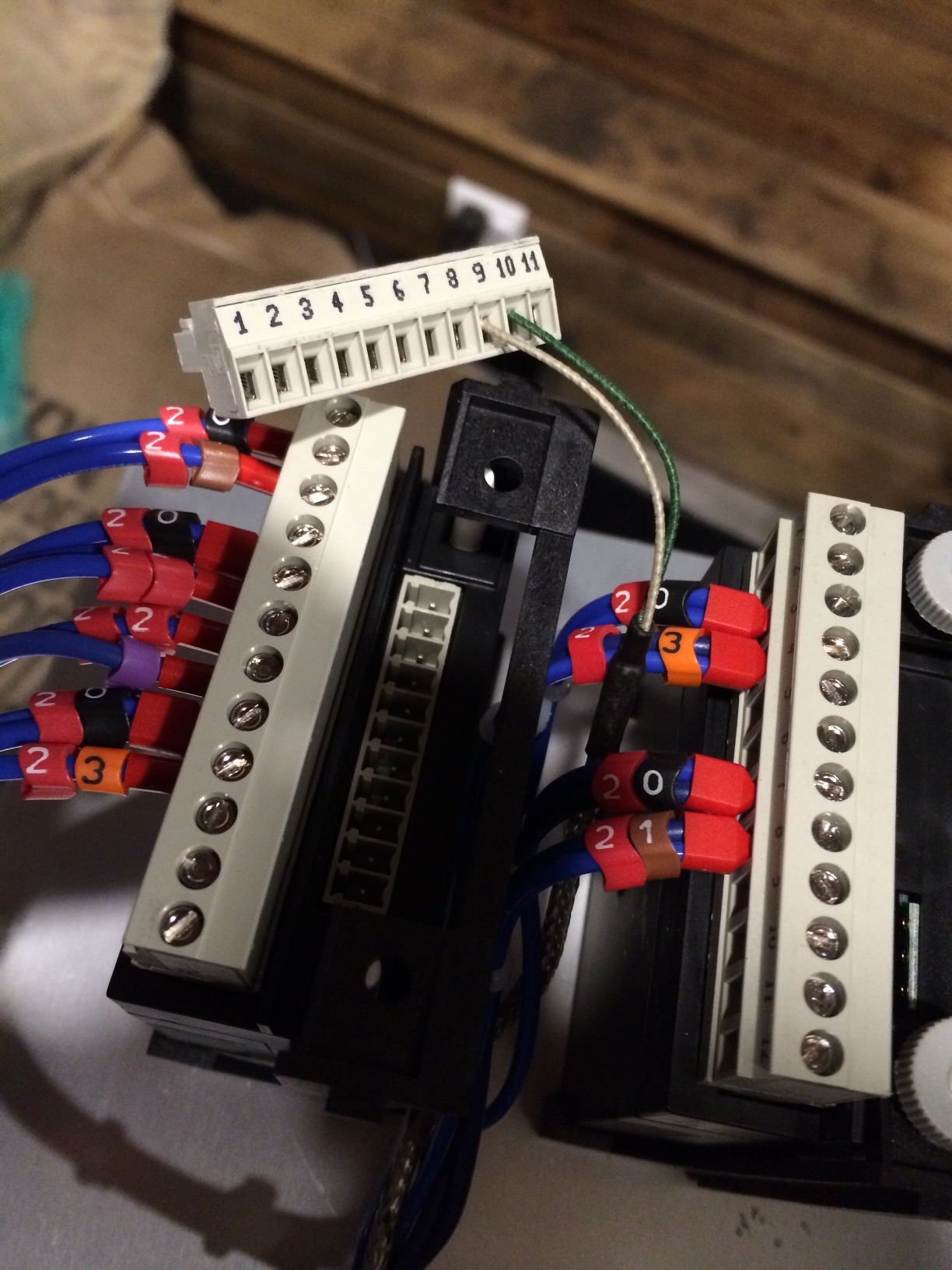

If you aren’t sure what type of thermocouples you have, you can send us a photo of your probe wires. Best is to follow the probe cable from the probe to its other end and make a photo of the wires at their connection point. Their colors will tell us more about their standard. Check out this page for a schematic display of possible color/origin combinations for for thermocouples or contact your thermocouple supplier. Also, to speed up the process, please let us know the make and model of your roaster, and the year it was produced.

Above: K type thermocouples in a Probatino. The green/white insulation colors indicate that these probes are manufactured to European standards and are K type.

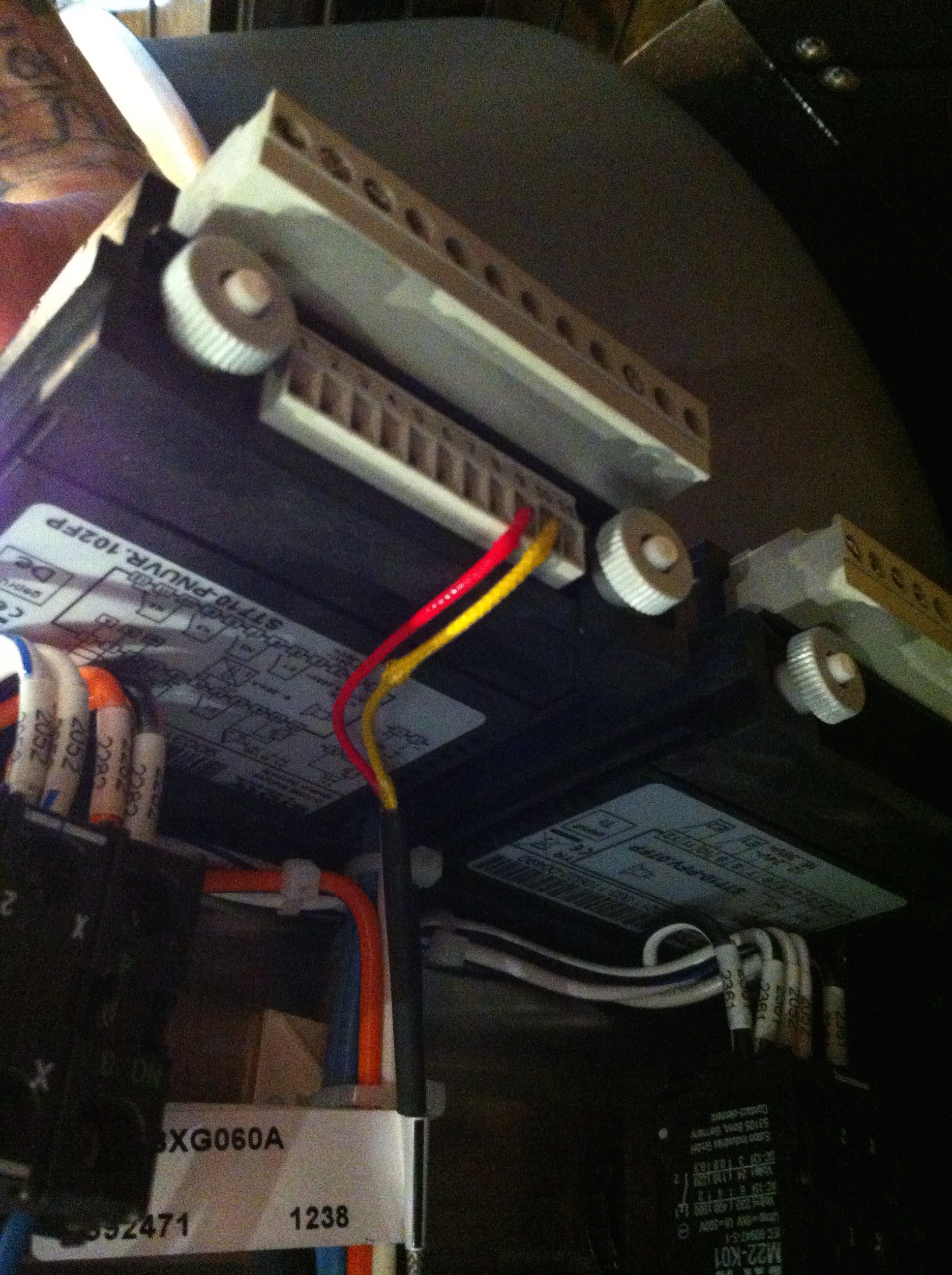

Above: Another example for K type probes. Red/yellow colors indicates American standard K type probes

What does ungrounded mean?

Ungrounded probes and grounded probes are slightly different but can make a significant difference in your readout. In ungrounded probes, the sensor inside the probe does not touch its tip, making it less sensitive to ground loops. In grounded probes, however, the sensor does touch the housing inside which makes these probes more erratic, over-sensitive and they will fail if you introduce another ground while using Cropster software. This means you can’t plug in your macbook while roasting.

Luckily, grounded probes are not very common any more. In case, you may check your probe with an ohmmeter and if the readout is INFINITE, your probe is ungrounded. If it reads anything else, you might have a grounded probe. In the long run your best bet is to replace grounded with ungrounded thermocouples for the best readouts.

B) RTD Sensors: PT-100/PT-1000

Unlike thermocouples, we cannot directly extend an RTD signal from a display and feed it into our software. Unless you do not want to use your current digital readout, we recommend installing a replacement dual/duplex probe. RTD sensors can be found in Giesen, Ambex, Bühler, Atilla and often in older, retrofit machines.Dual probes can be sourced pretty easily and replace your existing probe to allow connection to your display and Cropster at the same time. We do not recommend removing your probes from your existing readout as most function as your emergency shutoff and alarm systems.

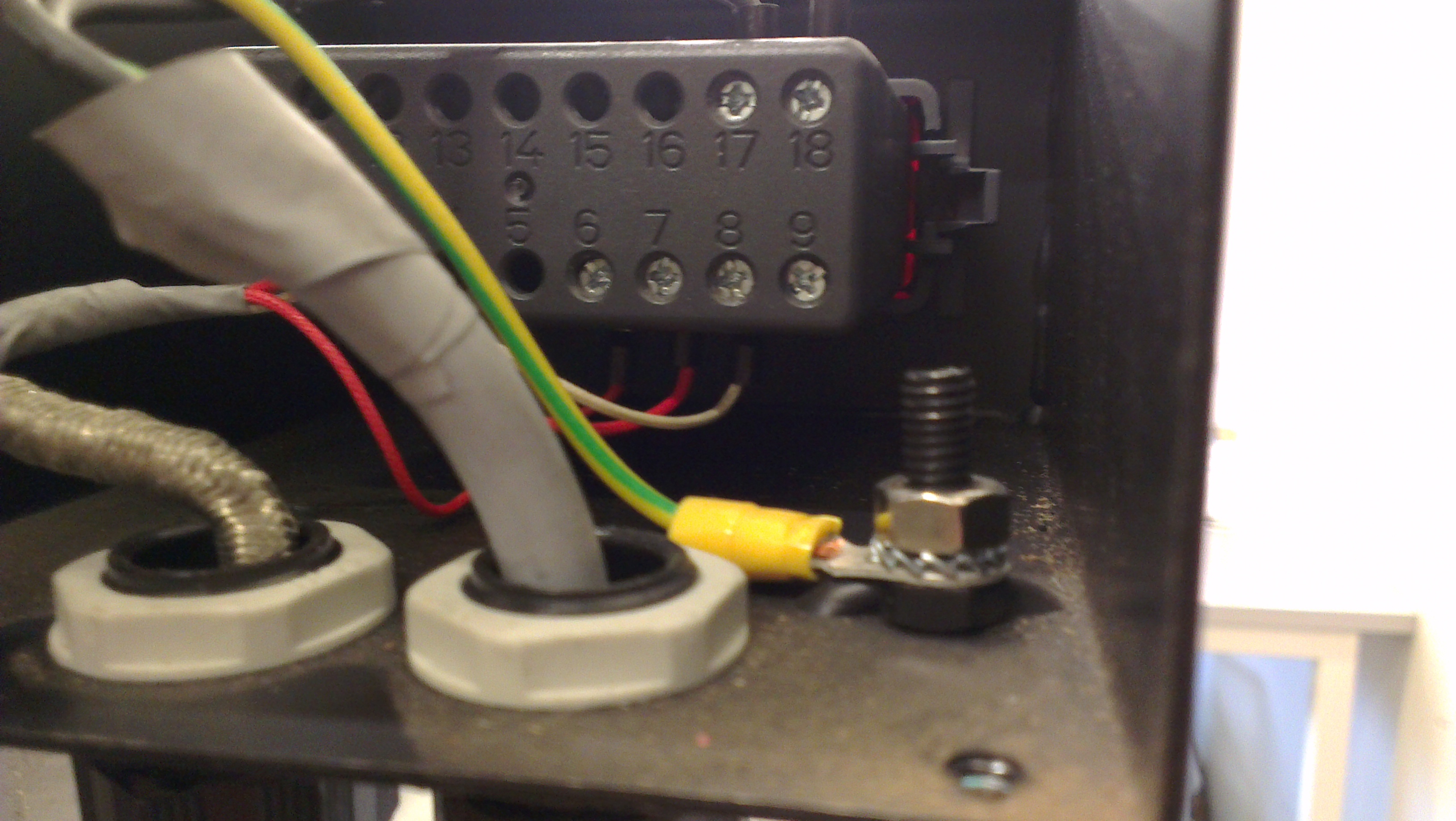

Above: A standard RTD connection in a refurbished old roaster. RTD wires typically have 2-4 wires per readout with red/white insulation and only require 2 for a Cropster readout.

If you can roast with it, you can use Cropster with it.

Whether you are a roastery who has Cropster on a machine or not, now might be the time to try setting up Cropster on the machines that are not. Connecting your roast machine to Cropster is the starting point to use our green coffee and roast production management tools, our roast profiling tools, our roast compare reports and QC features. We have support people who are more than happy to walk you through the process and help you source replacement probes and hardware if you need it!