Managing Uncertainty with Cropster: Roasting Efficiently

| Roast

Written by Marcus Young

Table of Contents

Throughout the day, roasting machines need cleaning and preventative maintenance. At the beginning of a roasting session, a machine is preheated and green coffee staged. During roasting, the machine operator needs to focus on the details of every batch. After roasting, the machine needs to recover, and the hopper loaded for the next batch. There is a lot of work involved during a typical roasting day! With efficient roasting principles, you can find significant cost savings.

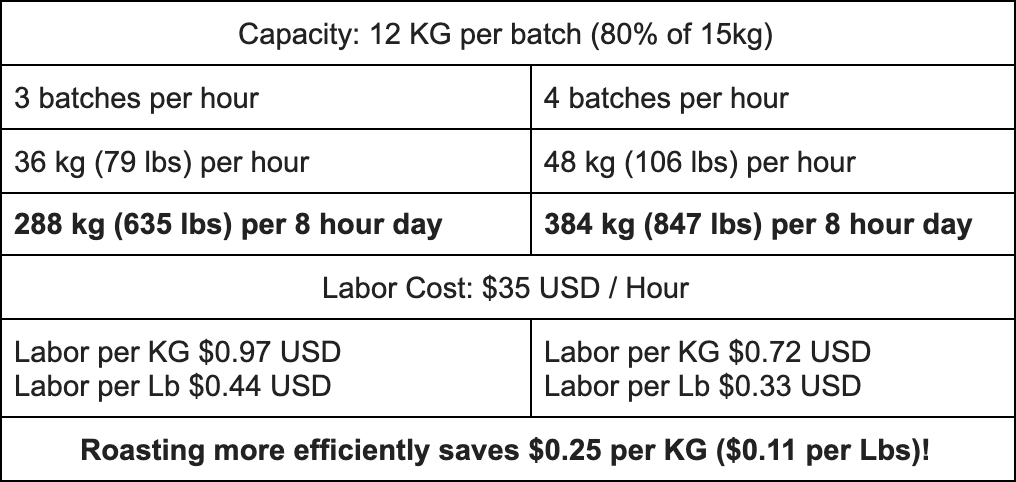

Roasting more batches per hour saves roasting companies significant labor hours compared to a less efficient operation. During an 8 hour production shift, roasting four batches per hour versus three batches per hour means you are 25% more efficient and represents significant labor savings! This also assures you are maximizing your production capacity and you aren’t as likely to outgrow your equipment as quickly.

Here’s one example, based on an 8 hour roasting shift, using a 15KG roasting machine operating at 80% capacity.

These are real cost savings – something more important than even in times of uncertainty over the cost of green coffee, and an ever evolving sales landscape brought by COVID-19 and changing consumer habits. Two topics we addressed earlier in our Blog series on Managing Uncertainty. Once a production plan is established, it’s up to the roasting team to execute that plan efficiently and with a focus on quality and consistency.

Starting Your Production Day

At the start of a roast day (after checking that your machine is clean, safe, and ready to operate) the next task to undertake is to start the machine and burner and preheat to your optimal warm-up temperature. (I usually heat to approximately 10% hotter than my charge temperature.) Preheating your roasting machine at the start of a roasting session is an important step that helps ensure consistency from first batch to last.

Once at the desired set point, idle your machine at temperature for at least forty-five minutes (your times will vary depending on the type and size of your roaster). While the machine is idling, it is the perfect opportunity to review your production plan for the day and to use your production reports to accomplish the following tasks with your team.

- Weight out all the day’s green coffee batches and stage them for roasting.

- Know how many bags of each coffee need to be prepared.

- Know the amount of which coffees we will blend.

- Visibility into how much of each coffee is to be ground.

- Prepare packing slips, boxes, and other details needed for fulfillment.

This is a lot of work to prepare, and using the time while the machine preheats gives you a chance to take care of these details. There is a quality benefit too. By focusing on these pre-production tasks during the roaster’s warmup, and not trying to take care of them during a roasting session, roasting personnel can focus solely on roasting while they are standing at the machine.

More attentive roasting equals more consistent and delicious coffee! It also frees up the roaster operator to quickly tag and pull samples for quality control, weigh roasted batches and compare roasted to green weight (a key QC measurement), and take color measurements of each batch.

Cleaning and Preventative Maintenance

An efficient roasting operation is also one that minimizes downtime and maintenance requirements. By utilizing a series of checklists and maintenance tasks, equipment will operate more effectively and reliably. Roasters should operate from a check-list of activities that need to be performed for every batch (e.g. ensuring the hopper is fully emptied into the drum at the start of roasting, the burner chamber is clean, the cooling tray is fully discharging coffee).

There are other tasks that occur every hour or after a certain number of batches. These tasks include cleaning the chaff collector, emptying any chips and embers from the gap between the faceplate and the drum, and wiping coffee oils from surfaces.

At the end of each day, and throughout the week, other more involved tasks might include cleaning the cooling tray, disassembling the smoke stack for deep cleaning, adjusting drive belts and lubricating chains, checking the roaster exhaust and fans, and other more involved maintenance tasks. It’s important to develop systems to keep track of these tasks, hold staff accountable for accomplishing each activity, and log and archive these activities for future reference. (If you ever have a warranty or insurance claim, they will want evidence that everything was maintained precisely to manufacturer recommendations.)

Between Batch Protocol

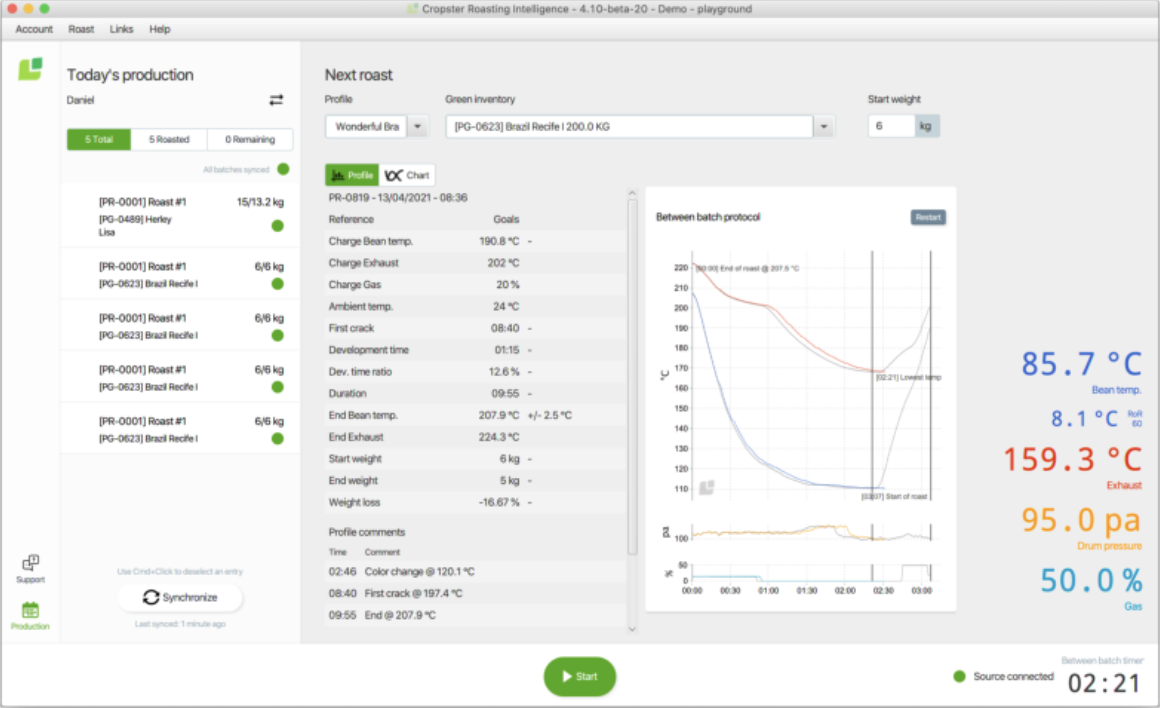

The ability to quickly rebound from the end of one roasting batch and start the next batch as quickly as possible is essential. We’ve already discussed how having green coffee staged for an entire production day is one element of efficiency. Another is how the roaster is brought back to an appropriate charge temperature between batches. Cropster’s Between Batch Protocol, built into Roasting Intelligence, helps roasters to visualize, formalize, and make routine the tasks roasters are already doing between batches.

Between Batch Protocol in Cropster Roasting Intelligence

Most roasters have some sort of between batch process in place. Generally, it’s an ad hoc approach where they target a specific charge temperature using either exhaust temperature or bean temperature (or a combination of both). Roasters then charge either with the temperature increasing or the temperature decreasing. This approach doesn’t consider the size of the flame, the heat cycles between batches, or the time between batches. Without these details, it is much more challenging to match a reference profile in the early stages of roasting and is less efficient.

One way to improve your roasting efficiency is to use Cropster’s Between Batch Protocol which extends the details of your profile beyond the start and end of roast, and now provides a timer and visualization of gas and environmental/air temperature, gas settings, air pressure, drum speed, and other machine controls during the time between batches.

This makes it more efficient for roasters to identify the starting point of their next roast. Without this information, roasters waste time waiting for the roaster temperature to drop, manipulating gas and air flow to reach and maintain their charge temperature. Often in the busy workflow of a roasting plant, it’s easy to miss those targets, requiring the operator to return to temperature and start the process over again.

Between Batch Protocol in Cropster Roast Compare Report

If a roaster takes 10 minutes between batches, they are roasting much less efficient than a roaster using BPP who might only take 5 minutes between batches. This could mean the difference between roasting 2-3 batches per hour versus 3-4 batches per hour with Between Batch Protocols. This represents a significant increase in daily roasted capacity, and by extension cost savings in the roastery.

With an organized roastery, staff is more focused on quality and they roast more coffee each hour. When equipment is maintained regularly, it operates longer without requiring downtime repairs. With between batch protocols in place, it’s easier than ever to move from one batch to the next efficiently. Finding efficiencies leads to real, measurable cost savings and benefits in your roasting company – something more important than ever in times of uncertainty and in an increasingly competitive environment.

Want to Learn More?