Production Consistency

| RI

Table of Contents

A coffee company’s efforts at consistency often begin with their green coffee purchasing decisions and extend all the way to the activities of baristas in the cafe. The roaster sits at the center of this, and the decisions made by the roaster can maximize consistency in the cup even when different green coffee components are involved or as green coffee ages. The efforts of the roaster can make coffees more forgiving and consistent for consumers to brew and baristas to prepare. In future articles, we will discuss consistency at the cafe. Here, we look at the techniques that roasting departments can use to ensure consistency.

Profiles

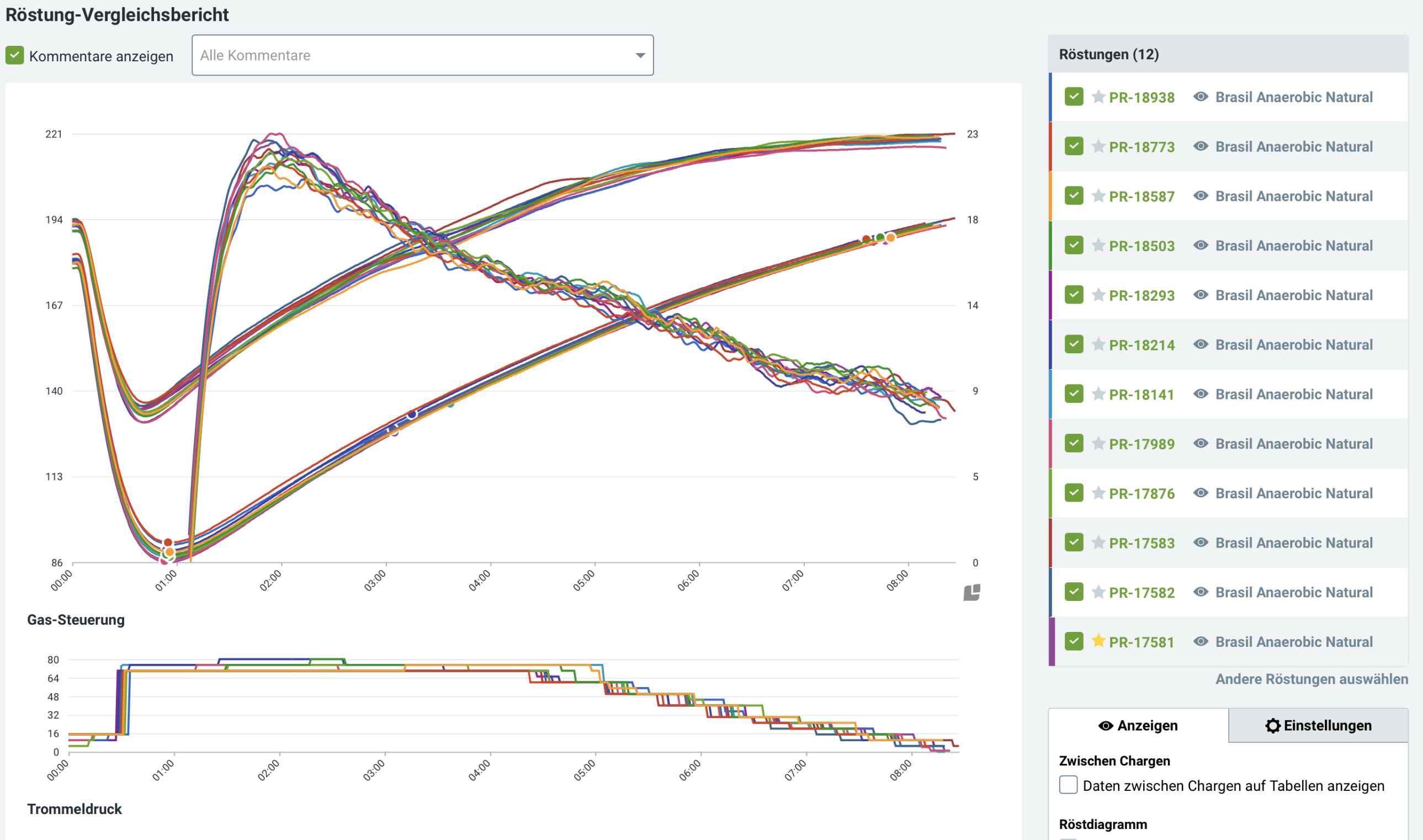

Roasters work hard to be sure their production batches match the roast profiles and recipes they have in place. One of the key tools that roasters use is Cropster’s Roasting Intelligence to ensure consistency and to execute a set profile for each production batch. Using Cropster’s Roast Compare, production managers can compare all the key metrics of a roast to a reference, seeing at a glance if the production profile was consistent with the recipe.

The metrics of a good profile include consistency in batch size, between batch protocols, charge temperature, the bean time and temperature curve, the air time and temperature curve, the bean temperature rate of rise (RoR), and the ending temperature and time.

Many roasters observe the development phases during the roast. An analysis and comparison of the time spent in the drying phase (from charge to color change to yellow), maillard phase (colloquially considered the time from yellow color change to the start of first crack), and the development phase (time from the start of first crack until the end of their roast) can show consistency batch by batch.

There are also physical and measurable attributes in a final batch of coffee, which roasters use to assess how close a production roast is to a reference recipe. These would include matching a consistent end roast color, matching the percentage of weight lost during the roasting process, and sometimes hitting a target density and moisture content for roasted coffee.

Roaster Controls

One challenge for a roaster is matching production profiles to reference curves when there are variations in the ambient conditions. The coffee will roast differently on a hot day than a cold one, while humidity and barometric pressure can affect heat transfer in the roastery.

The roaster needs to take this information and act on it using the controls of their roasting machine. Common roasting controls include gas pressure, airflow, and drum speed. Depending on your roasting machine, Cropster’s Roasting Intelligence can chart and log these changes throughout each roast, and compare the current control settings to the saved reference roast. In many cases, your roasting machine will allow you to control the gas, airflow, and drum speed directly in Roasting Intelligence.

Cropster’s between batch protocol chart provides roasters with a starting point for each roast and shows the necessary data to make relevant adjustments based on ambient conditions. This can also alert you to when things are going wrong – such as a full chaff collector, dirty ducting, or other issues.

Batch Size, Aging Green Coffee, Ambient Conditions

A master roaster can take all of this information, their skills on their roasting machine, and knowledge of the coffee to execute roast after roast with a profile that is consistent not just in the shape of the roast curve, but in the final cup. This is an enormous challenge when batch sizes change, the environmental ambient conditions are highly variable, and/or as green coffee ages.

How a roaster adjusts their machine to account for these changes is highly variable, and this is one attribute that makes every roaster (and every roasting company) unique in the coffees they produce. One example of variance is the relationship between drum speed and batch size. Larger batch sizes can be run with a slightly slower drum speed than a smaller batch. When you change batch sizes, the relationship between conductive heat transfer (drum to bean and bean to bean) and convective heat transfer (heating the beans by the roaster’s airflow) changes. As you change the drum speed, this relationship between conduction and convection also changes. Skilled roasters will play with their drum speed in order to maintain consistency in the final cup. Another example is roasters who manipulate the airflow and airspeed in the roaster, managing the balance between conduction and convection.

The upcoming release to Cropster’s Roasting Intelligence brings the control of drum speed to the roaster operator within their Roasting Intelligence environment – adding to the controls of airflow and gas pressure, and giving them even more control to achieve consistent roasts.

Quality Assurance

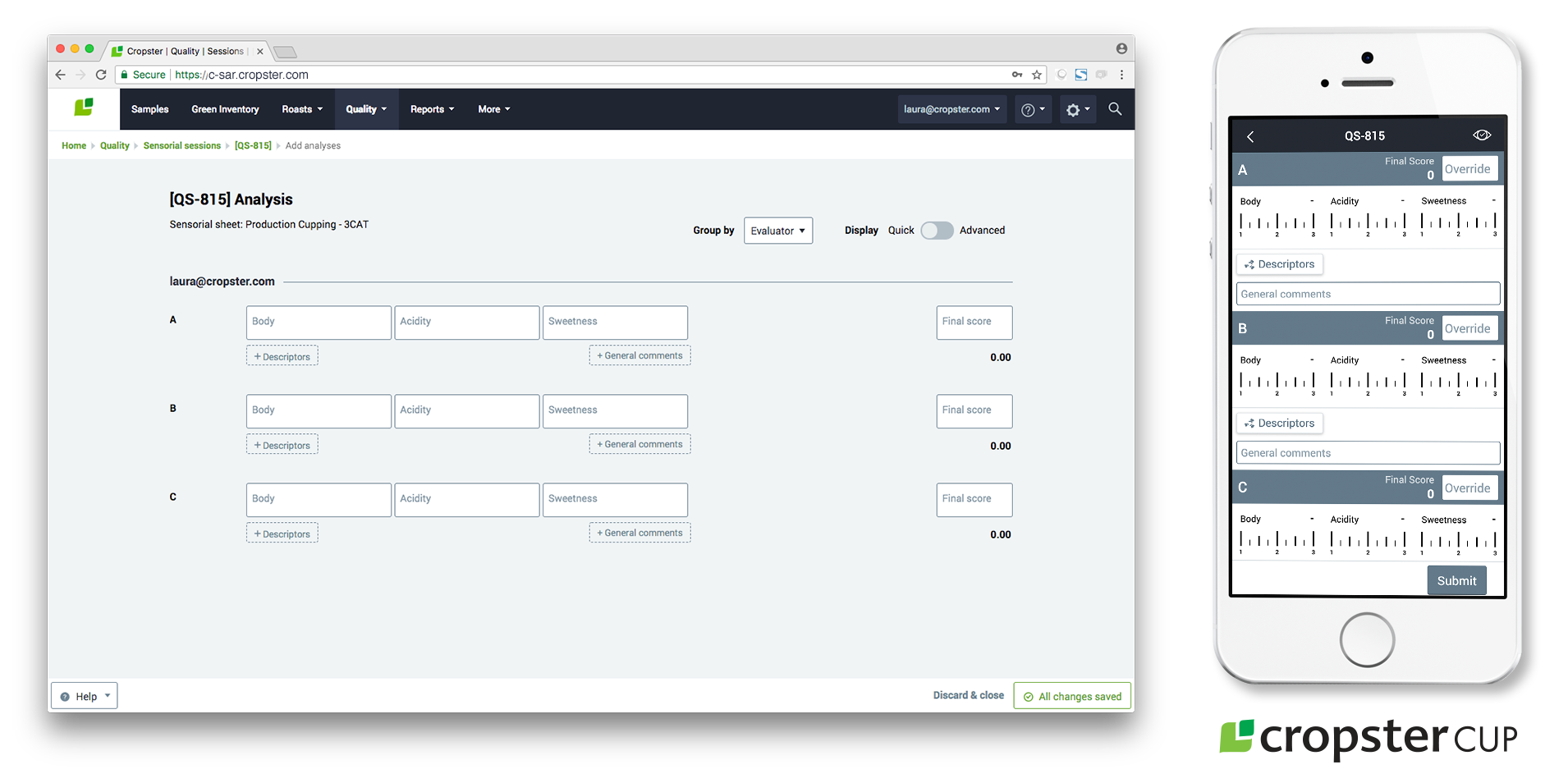

Once the coffee is out of the roaster, there are several critical quality assurance steps. Cupping production batches, using Cropster Roast Compare report to analyze one roast against another, and using Roast Goals to assess the key metrics defined for production batches against a recipe are all techniques available to roasters to assess the coffee’s consistency and quality, and, to learn from and improve their word as time goes on.

The more detail oriented roasters will go further and use specific types of sensory tests like a triangle test or an in/out test to compare an acceptable reference batch to a questionable batch. In these tests, there are at least three cups per set (two of coffee A, one of coffee B, for example). Across multiple sets, cuppers will identify the odd cup. If the tasting panel cannot consistently identify the odd cup, the coffee would pass this quality assurance test and be released to customers. Statistical rigor can be applied using a series of statistics tables designed around triangle tests or in/out tests.

It is important that quality assurance extends beyond formal cuppings, and that one prepares representative samples of roasted coffee in a batch brewer, on an espresso machine, or as cold brew, etc. Ideally the quality of the final product is assessed in the same way that customers prepare their coffee.

Quality assurance doesn’t stop at the roastery either. Some roasters pull samples from grocery market shelves, others place dummy online orders and have the coffee shipped to them for testing.

Ideally, roasters test the coffee for consistency at every step. Directly out of the roaster in a production cupping, triangulating any batch that’s “questionable” when viewing roast goals or production processes, tasting the coffee prepared in a variety of different brew methods, and tasting the coffee to assess packaging integrity, shelf life, and other factors once the coffee leaves your immediate control. Cropster Cup has several cupping forms available to aid in quality assurance. With the ability to link a production batch to the green coffee input, Cropster Cup helps keep all of this data organized, and provides the data insights to take action when there is a problem.

Cropster Cafe takes this one step further, and gives baristas in your cafes the tools to prepare consistent coffee according to company standards, and for roasters to have visibility into the tasting notes and quality assessments made that the retail store identified.

The brew parameters and equipment settings are to a barista what the roast profile is to a roaster. Cropster Cafe supports the retail side of the business to organize and track brew recipes as they change throughout the day and weeks, working to keep the coffee delicious and to meet customers’ deeply ritualized expectations of consistency. Cropster Cafe includes built-in brew tracking records on how brews change throughout the day and an integrated task management suite, mitigating the risk of a lapse in equipment maintenance that could jeopardize operational consistency.

Producing consistent coffee is a key skill of a coffee roasting company. By measuring and monitoring data, knowing the coffee and roasting machines, and with frequent and intentional tastings, roasters move closer to providing the consistent product that their customers demand. While it might sound like a lot of data, steps, and procedures to track and manage, taking the time to improve your roasting and brewing consistency is an important part of running a modern roastery. Cropster helps make it as easy as possible.