Kaffee Panel Series – Part 3: Sebastian Kohrs

| Roast

Roasting expert: Sebastian Kohrs

Roasts at: Elbgold

City / Country: Hamburg / Germany

Roasting machine: Probat G-45 (Kirsch & Mausser)

Green coffee: Bomb Anaerobic, Ethiopia, various, by Faysel A. Yonis

Kaffee Panel Review: 91.89 points

Sebastian Kohrs started his professional career as a copywriter. He told us he quickly discovered working with jumbled and confusing text was not for him and he looked for alternatives. After a short stint as a chef, he made his way to Elbgold. He joined their team 7 years ago and is now responsible for their entire production as Head Roaster. In the Africa edition of the Kaffee Panel, he won 1st place in the “various preparation” category with an Ethiopian filter coffee.

Preparation and selection of the green coffee

Sebastian has been purchasing coffee from the African producer Faysel A. Yonis since 2017. He is convinced of the quality of the coffee and, with his selection for the panel, wanted to show how professionally coffee is handled in Ethiopia. With this coffee the first phase of anaerobic fermentation in a plastic barrel lasted 120 hours, then the oxygen was removed. The barrel was then filled with water so no more oxygen could get into it. The metabolism of the microbes was strongly stimulated in the airtight container and as a result, a large number of lactic acids and yeasts arose. No other flavor carriers were added, as the coffee should be preserved in its naturalness. During a 5-day fermentation process, the sugar and pH levels were regularly checked. After 120 hours, the cherries achieved a desired pH value of 4, giving the coffee an extremely high acid content. The cherries were then dried in the sun on the special drying beds. To achieve consistent drying, the cherries had to be turned every 30 to 60 minutes. All the cherries were brought inside at night to avoid condensation. As soon as the cherries had a moisture content of 35%, they were further dried in the shade for 39 days. The temperature was now constant at 16 degrees. Over fermentation was avoided with tight quality controls. After pulping, the beans were warehoused until shipping.

“This type of anaerobic fermentation makes coffee very exciting. The green coffee contains a lot of lactic acid and the taste profile after roasting is very different from other coffees.”

Sebastian Kohrs

Elbgold

Approach, objectives and profile development

Normally, comparative values from different coffees can be used for the roasting process. In addition, there is a certain taste concept that the roaster already has in mind. Everything works differently with anaerobic green coffee. Sebastian Kohrs had already bought three versions of this producer’s green coffee: washed, natural and anaerobic natural. Therefore, he could use his experience with natural green coffee as a starting point for the sample roast. For him, extremes should be explored with sample roasting. Ultimately, we all know sample roast profiles from an Ikawa cannot be transferred to a Probat. During sample roasting, it is more about testing the reaction of the beans to shortened and extended drying phases, the Maillard phase and the development time.

“By default, we pay attention to the moisture and density of coffee during the roasting process. What kind of energy can I approach the coffee with? Should I focus on direct contact heat or perhaps more air heat? How high does the filling temperature have to be depending on the volume in the roaster?”

Sebastian Kohrs

Elbgold

After Sebastian Kohrs developed a feeling for the coffee with the help of the sample roasts, roasting started on his Probat G-45. Various profiles can be programmed on this machine. Once the green coffee has been dropped, a profile can be automatically started by pressing the contact switch. However, stored profiles of other Ethiopian coffees could not be used, as the high acid content of this coffee necessitated a different approach.

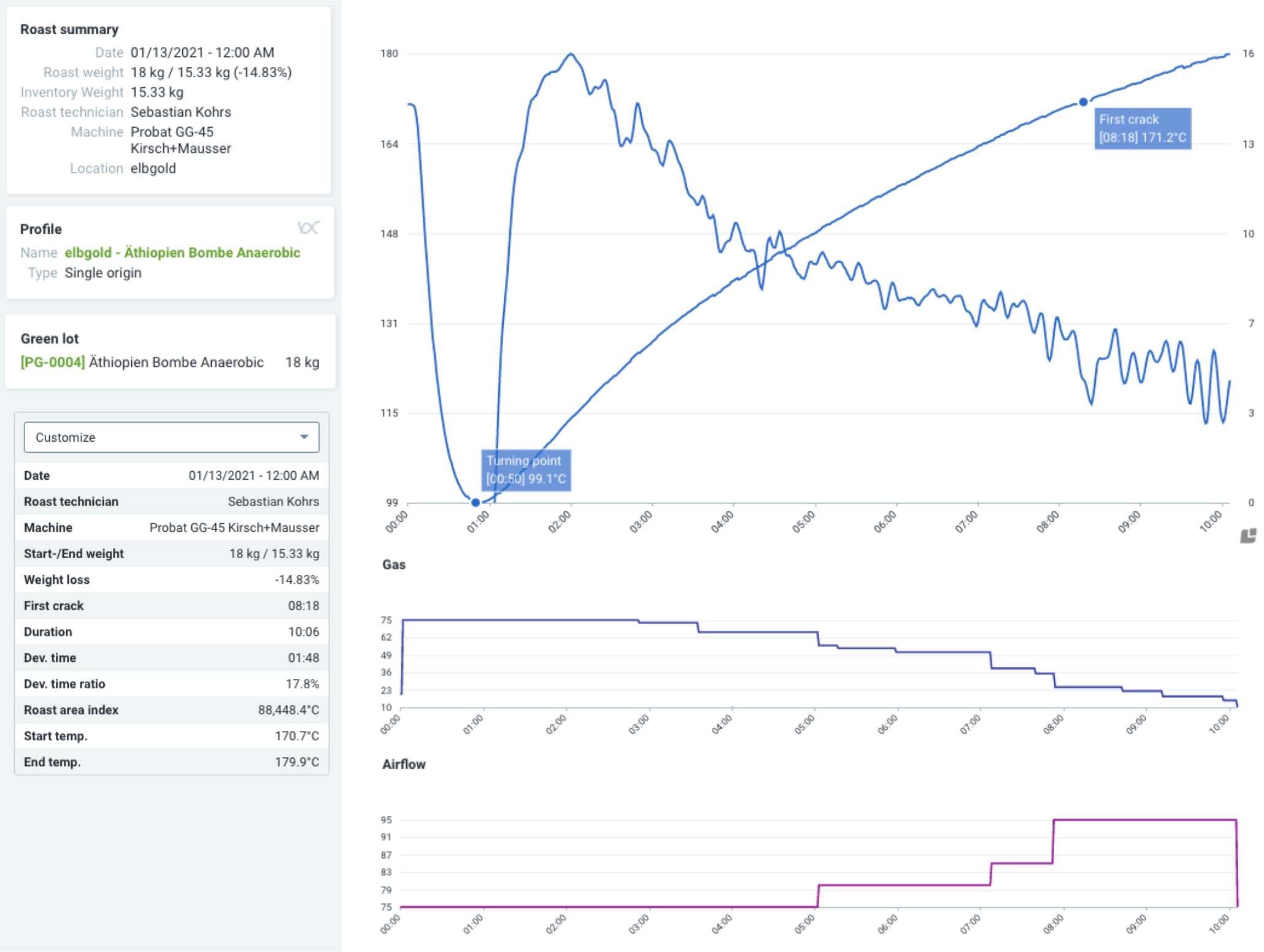

Description of the roasting process

The award-winning coffee was roasted with a batch size of 15 kg on the Probat G-45. With this smaller batch size (for a 45kg roaster machine), the interaction of gas output and airflow must be precisely controlled. Luckily, drop size adjustments are part of day-to-day business at Elbgold, so there was no reason for concern. The charge temperature was 180 degrees Celcius. The drying and Maillard phase were held a little longer than usual. Especially in the drying phase. Also, the gas output was kept low, in order to keep the heat transfer very even. This was done with a view to the body and the complexity.

“You can see from the airflow setting that the drying phase ended at around 4.5 minutes and the 3.5 to 4 minute Maillard reaction begins. This creates a relatively soft and unusually supple body for an Ethiopian coffee. ”

Sebastian Kohrs

Elbgold

The profile shows that the gas and airflow curves converge like a staircase. Before first crack, airflow was significantly increased for two reasons: the coffee needs to be cooled a little further to shorten the development time and the anaerobic coffee behaves very differently than the washed and natural variants. This measure was taken because of the high acid content, which could otherwise pull out too much of the aroma.

“You have to pay close attention to the acidity and create the right balance.”

Sebastian Kohrs

Elbgold

The roasting curve of the Kaffee Panel Roasting Latin America by Sebastian Kohrs, Elbgold

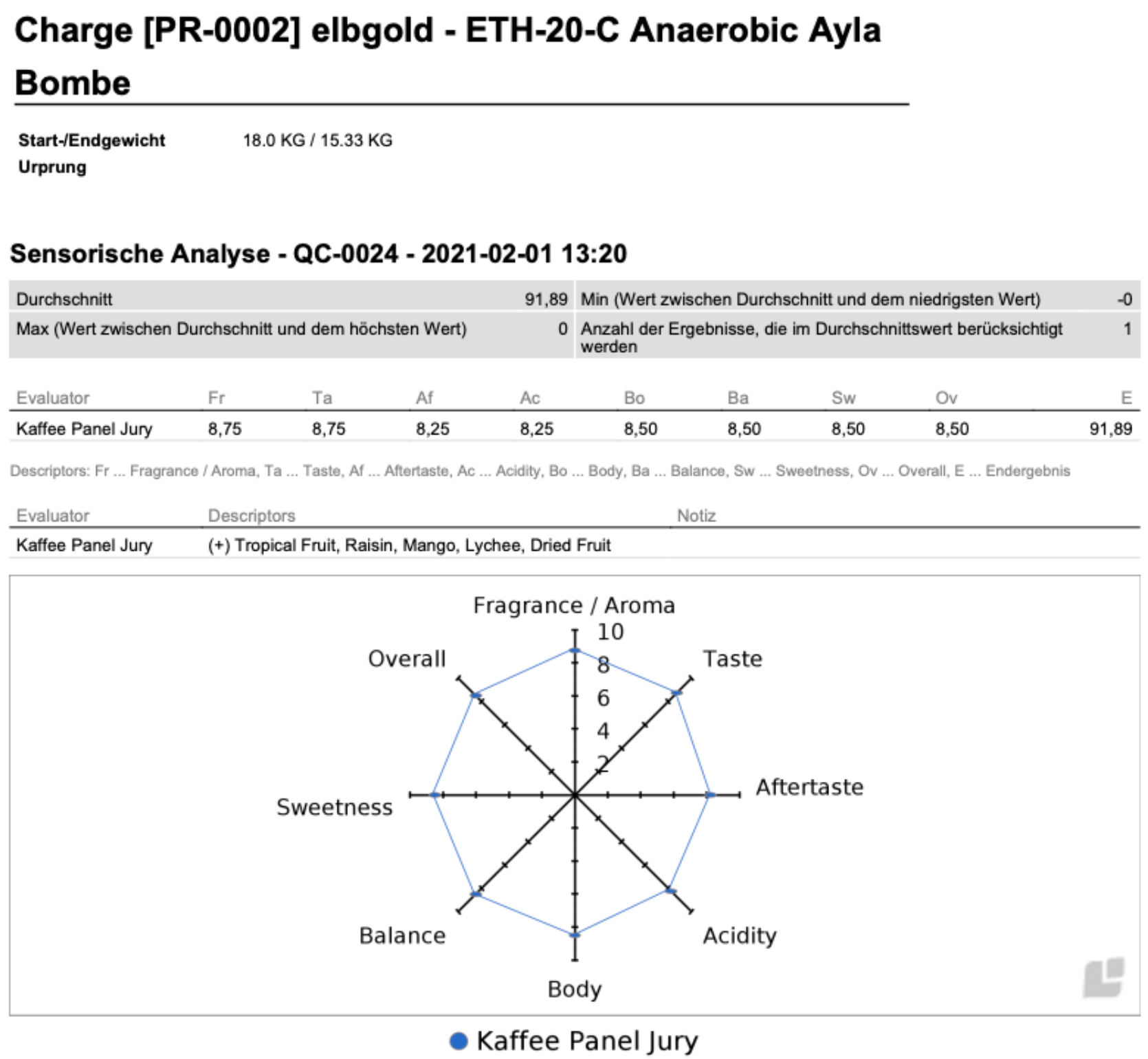

Analysis of the roasting and the tasting result

Philipp Schallberger was particularly fond of this coffee. It achieved a very high cupping score of 91.89 points. To put this score into perspective it should be noted, the Q-Grader Score was not used as the basis for the calculation, instead they used a slightly modified system. With this change in evaluation basis, sweetness is of great importance, so a further 4 points were added. The many steps in the production of the green coffee and the roasting process show the challenge this green coffee presents the roaster with its very high lactic acid.

“I especially like your approach to taming the acid. In my experience, when you tame something, it results in a denser and softer texture. “

Philipp Schallberger

Die Kaffeemacher

The result of the tasting of the Latin American Kaffee Panel jury for Elbgold

The dense and very soft texture gave the impression that the coffee was sticking to the tongue. In terms of taste, the coffee delivered a real explosion of intensity. Fruity flavors of strawberries, mango, lychee and peach combine with intense floral notes that point towards rose hip. Due to the acidity present, the coffee is reminiscent of a sweet dessert wine. The mango note is retained as a present note in the aftertaste. In order to achieve this density of flavor notes, every single step in production has to be worked precisely. Not a single cherry should be defective, because the very long fermentation could spread the defect to many others and result in harmful bacteria formation instead of the desired yeast.

“This production in particular is not yet a standard in Africa and relatively rare in Ethiopia.”

Philipp Schallberger

Die Kaffeemacher

It is therefore even more gratifying that this green coffee is produced at such a high level and that it literally deserves its name ‘bomb’ thanks to the roasting process.

Many thanks to Sebastian Kohrs and Philipp Schallberger for talking to us. We look forward to the exciting insights into the production and roasting of this green coffee as well as the willingness to share your thoughts with us.

In the next article in this series we will introduce another roaster and their roast for the Kaffee Panel.

You can watch the entire webinar on the Cropster website: “Cropster & Kaffee Panel 1: Interview with the Top Roasters Live (Africa & Latin America)”.

For more information on the Kaffee Panel and the announcement of the editions and placements, visit https://kaffee-panel.org/ or the coffee makers’ YouTube channel.