Customer Success Story: Bunista

| Roast

Written by Ines K

Table of Contents

Fast forward 10+ years and Bunista employees Khalid (Sales Support) and Tony (Operations manager) pointed out that “The popularity of drinking good quality coffee in the Middle East grew in the past 5 years, so people have started to see the value of specialty coffee and are also willing to pay for it.”

Bunista was one of the first brands serving specialty coffee in Saudi Arabia. The name bunista comes from “bun” which means coffee bean in Arabic and the word barista, referring to someone who serves great coffee to customers. Bunista is the specialty brand under the umbrella of Marabih. Other coffee businesses that are part of Marabih are green coffee importer Kafa (partnering with Cafe Imports), specialty cafe Oka, coffee hub Jamoka, and many more.

Machines:

Production roaster: Diedrich IR 12

Sample roaster: Ikawa V1

Capacity: 12 kg

Customer since: 2018

# of cafes: 1 coffee shop within their roastery

Location: Al Khobar, Saudi Arabia

When the specialty coffee market gained popularity in 2018, Bunista was already present and followed their belief that good coffee should be accessible to everyone. As Tony said so nicely, “Coffee is part of our daily lives. Sometimes people are overwhelmed by the variety of coffee and that’s where we have to educate them. For the general coffee drinker, less is more.” Additionally, it’s important to Bunista that farmers get fair prices and can produce coffee sustainably. Often specialty coffee lots are only a small piece of what the farms sell but this part is where they make their living. That’s why “we needed to introduce high quality coffee and help define what that is to the market”, Tony added.

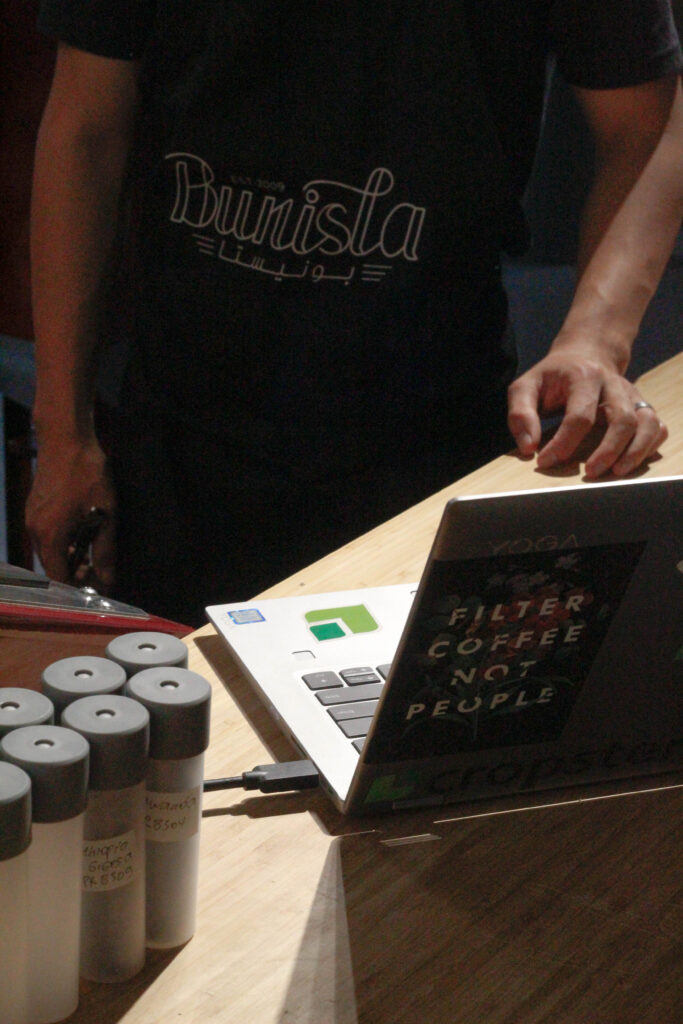

Photo credit: Bunista

Their Mission: Roast good green coffee to bring out the best flavors and quality.

From the start, Bunista knew that their goal and responsibility was to get the most out of good beans and to roast great coffee. They asked themselves: How do you roast to get the best out of green coffee and keep consistent quality?

When Tony started at Bunista in 2018, he tried to log his roasts on paper but it just got messy over time. He shared: “I was so focused on logging temperature and time on paper all the time, that I couldn’t focus on roasting with the Diedrich properly.” He realized that he needed more on the data logging side of things but also clearly saw that there is more to roasting good coffee than just tracking profiles. With Cropster, they found exactly what they needed. He added:

“If you just want to log your profiles, there are other solutions out there, however, if you also want a good tool for inventory management, quality control and production planning, Cropster was the best solution for us. It just helps to track everything, so that we can focus on improving the quality.”

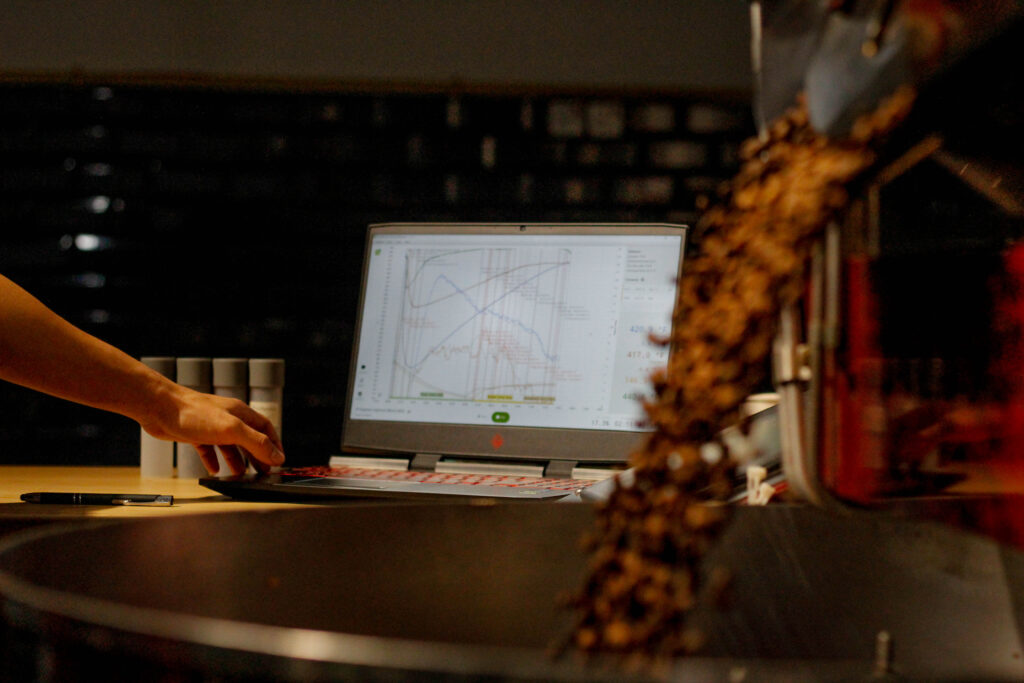

Photo credit: Bunista

The solution: Everything in one place with Cropster.

For Bunista, having a real-time and accurate view of their inventory is priceless. “Knowing how much green coffee is left in stock might be a basic feature for some”, said Tony, “but for us it’s very important and awesome that the green inventory is automatically deducted when you roast.”

In addition to Cropster’s inventory management module, Bunista uses the Order to roast feature. They’re especially happy about the Shopify integration which automatically sends all their incoming orders into Cropster, ready to be scheduled for roasting. This way, they can collect all their orders in one place which reduces errors. “We try to have all of our orders come in through our website, both for individual customers and wholesale orders. Previously, the amount of phone calls, emails and WhatsApp messages got a bit ‘crazy’ over time. With Shopify we now minimize the error of forgetting an order compared to when orders came in through multiple channels”, Tony explains. Moreover, it saves them valuable time. Before they started using Order to roast and the Shopify integration it took them about 1 hour each day to plan their production. Now, it takes them between 20 – 40 minutes depending on the amount of orders. Tony can still check orders in the evening before the production day and knows exactly how many and when to schedule additional roast batches. This was especially helpful during COVID-19 as online sales replaced in-person sales in their cafe.

Supportive during COVID-19 crisis.

Preparing everything from home with Cropster was very helpful during the lockdown in Saudi Arabia as they only had 5 hours per day for their operations. Thus, they needed to be as efficient as possible. Tony shared the following with us:

“I pre-planned the production in Cropster usually on the night before. Whoever was going into the roastery the next day, was presented with an up-to-date schedule. I mean the roast machine still needed to be heated up, but everyone always knew how many roast batches of which coffee needed to be roasted each day thanks to Cropster.”

Photo credit: Bunista

The Order to roast feature also helps them trace back the orders to the specific roast batch and green coffee. “This is especially great for quality reasons because if a customer reports that they are not 100% satisfied with the coffee, we can go back and check what batch it was.” says Tony and adds: “We always have evidence to back us up, thanks to the QC features in Cropster.” Another Cropster tool that they find very useful for their quality control is Cropster Cup. Tony told us that “It’s a great tool for quality control and it’s so much easier than writing it down on paper.”

Keeping track of environmental changes in the roastery

Bunista has also recently started using Cropster’s AmbientSensors to keep track of the environmental conditions in their roastery. It’s nice-to-have as the weather in Saudi Arabia often changes dramatically throughout the year with extreme weather conditions and differences in the temperature in the morning vs. the evening as well as in winter vs. summer. Tony shared that “It’s great to have an overview and to know what the challenges are. There is no guessing involved as we see the exact measurements at any time. This way, we can figure out how to adapt our profiles accordingly.”

The Bunista team. Photo credit: Bunista

Asked what they liked best about working with Cropster, Khalid and Tony agree that it is being informed all the time, whenever they need the information and wherever they are. Khalid said: “I get notified on my phone about what’s happening in the roastery although I am not involved in the roasting. It’s still nice to know what has been roasted on each day.” For Tony it’s just great to know that whenever he goes back to his home country of Indonesia, he still knows what’s going on in the roastery at all times thanks to Cropster. Finally, we asked Tony what his best advice would be to those thinking about using Cropster in their roastery operations. He recommends starting with Cropster earlier rather than later. He added: “It’s nice to have everything in one place. You can log all your roasts and work on improving your roasts, quality, and consistency.”