Kaffee Panel Series – Part 2: Carsten Wolters

| Origin

Roasting expert: Carsten Wolters

Roasts at: Roestbar

City / Country: Münster / Germany

Roasting machine: Kirsch & Mausser UG-22

Green coffee: Finca Vizcaya, Guatemala, washed, from Los Amigos

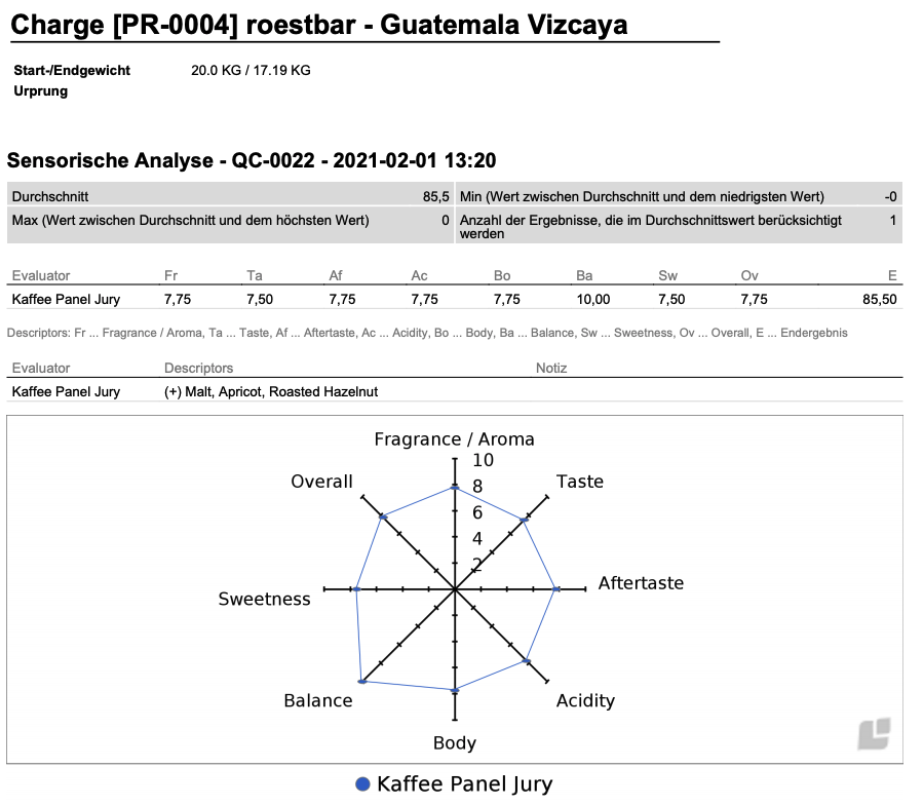

Kaffee Panel Review: 85.50 points

Roestbar has been involved in everything to do with coffee beans for almost 20 years. Today Roestbar includes several cafes that they supply from their own roastery. Carsten Wolters joined the Roestbar team in 2006 and has been a roaster there since 2012. Today as head roaster, he is also responsible for Roestbar’s product management. He roasts on a Kirsch & Mausser UG-22. In the Latin American edition of Kaffee Panel, he roasted a coffee from Finca Vizcaya in Guatemala and received 6th place in the “washed” category.

Preparation and selection of the green coffee

Carsten first discovered this coffee from Los Amigos / Finca Vizcaya from Guatemala by chance. The coffee has now been part of the Roestbar range since 2018 and quickly became a customer favorite. It is now one of the roastery’s most popular coffees.

“That’s why we wanted to take the opportunity to have it professionally assessed by a jury at Kaffee Panel. The feedback and the evaluation were not only important to us, but also to the farmers and importers.”

Carsten Wolter, Roestbar

Approach

Carsten Wolters first roasted a sample. The coffee samples were roasted on an older Probat sample roaster, which has an old school feel. He cites the total roasting time and the development time from crack to the end as key parameters. After roasting, production cuppings were done and the sample roast provided very good clues for planning the actual roast. At that point a roasting curve, in the classic sense, was not created. The aim with the samples is to work out the properties of the coffee as transferring roasting curves is not really feasible.

In this context, we wanted to understand how Carsten assesses the scalability of a roast. Can profiles be transferred from a small roaster to a larger one? In Carsten’s experience, scaling is not really possible, especially with drum roasters. He sees more potential for scaling in air roasters. He says that the energy supply depends on the amount of coffee beans being roasted. Fewer beans give off less energy, while more beans give more energy to the other beans. Each roaster has their own system which is primarily based on sensory and less on sample roasting profiles. Roestbar uses a sample roaster, however, the roasting curves cannot be transferred 1:1 to their production roasting machine. Sensory orientation is required to build the profile for each machine, and that requires individually recorded sensory information.

Description of the roasting process

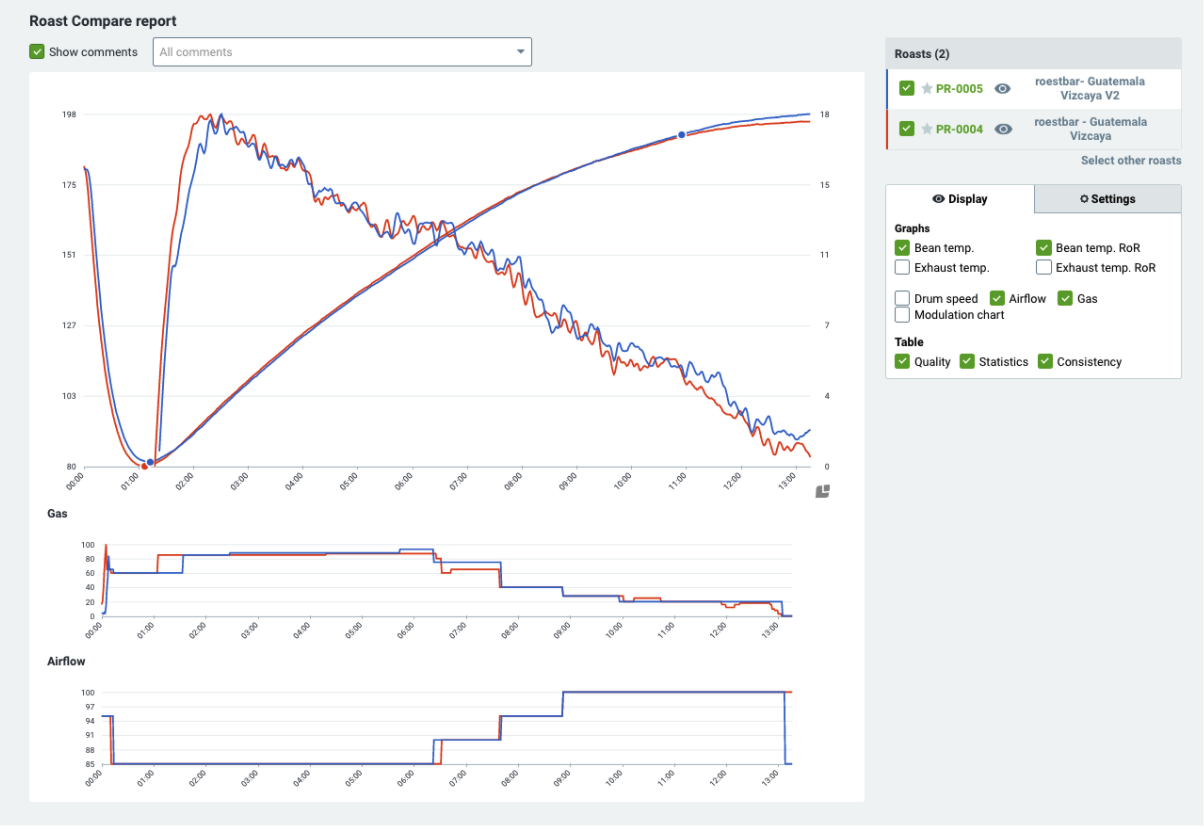

For the washed coffee from Los Amigos / Finca Vizcaya in Guatemala, some roast curves from previous roasts were already available. Two roast curves were shared with Kaffee Panel and Cropster for this webinar from the two roasts made for the Kaffee Panel review. It is worth noting that both roast curves are virtually identical. Carsten rarely sees this when roasting. But, in order to reduce a slightly hard taste from the first cupping, the final temperature was reduced during the second roast. The reduction was not particularly strong, but moved in a small area. Carsten pointed out: “We are of the opinion that even a 1-2 degree difference in the final temperature can greatly change the taste.”

The roasting curve of the Kaffee Panel Roasting Latin America by Carsten Wolters, Roestbar

Expressed in numbers, the final temperature of the first roast, which was not submitted to Kaffee Panel, was 198.3 degrees. The coffee submitted for judging was roasted with a reduced final temperature of 195.7 degrees. The development time of the final roast corresponded to the first roast. However, less energy was added in the middle of the roast in order to reach the lower end temperature at the end. This subtle difference could be tasted directly during the cupping. There was no longer any trace of the slightly hard taste initially detected.

Approach, objective and profile development

For Carsten the first roast of the coffee was not completely convincing, the aroma of the coffee needed to be cleaned up a little by reducing the final temperature. Also, its subtle acidity needed to be brought out more. “Our goal with the roasting was to produce a coffee with a high balance, which does not have a very strong acidity or sweetness, and perfectly embeds all properties.”

Carsten also explained that this goal results in a different approach for other coffees, for example from Africa. Kenyan coffees are known for their pronounced acidity and have very fruity notes with rhubarb and red berries, especially currants. With those coffees, he adapts his roasting process to highlight and balance these notes. Carston’s opinion as head roaster at roestbar is that a balanced coffee is a very good product. For an individual and tasty coffee, however, the special notes are important. These are amplified by reducing the roasting time and developing time in his experience.

Analysis of the roast and the tasting result

Philipp Schallberger was particularly impressed by the balance of this coffee. Compared to the coffee from Günther Coffee Roasters presented in Panel 1, he did not find a single outstanding attribute, but praised the balance of the notes:

“This coffee is a very good example that not every coffee has to have extreme properties to be tasty, but can also be very harmonious in itself.” Philipp Schallberger, Kaffeemacher

The result of the tasting of the Latin American Kaffee Panel jury for Roestbar

When comparing the two roasts, Philipp found that the second roast, where the final temperature was reduced, had a more developed sweetness. For a filter coffee, the coffee had a slightly longer roast profile. The development time showed an increase of 18%. With the RoR you can see that it drops very gently towards the end (up to almost 0). Philipp Schallberger explained that not every coffee can be roasted with this approach, especially when roasting filter coffee. Only very high quality green coffees allow this type of handling. As a result, he concluded that Carsten Wolters had a very high-quality green coffee available with the washed coffee from Los Amigos in Guatemala. In his closing remarks, Philipp once again emphasized the balance of the coffee and the balance of the roast:

“Drinking this coffee was a lot of fun and is definitely something for every day and every person.”

Philipp Schallberger, Kaffeemacher

There were hardly any differences or surprises in the jury’s assessment compared to our own rating. Our evaluation model differs from that of the jury, as we do not evaluate according to scores, but more simply. We are particularly pleased about the very positive assessment of the balance of the coffee and thus also the strength achieved.

Many thanks to Carsten Wolters and Philipp Schallberger for the information about roasting and their willingness to share the analysis and assessment with us.

In the next article in this series we will introduce another roaster and their roast for the Kaffee Panel.

You can watch the entire webinar on the Cropster website: “Cropster & Kaffee Panel 1: Interview with the Top Roasters Live (Africa & Latin America)”.

For more information on the Kaffee Panel and the announcement of the editions and placements, visit https://kaffee-panel.org/ or the coffee makers’ YouTube channel.